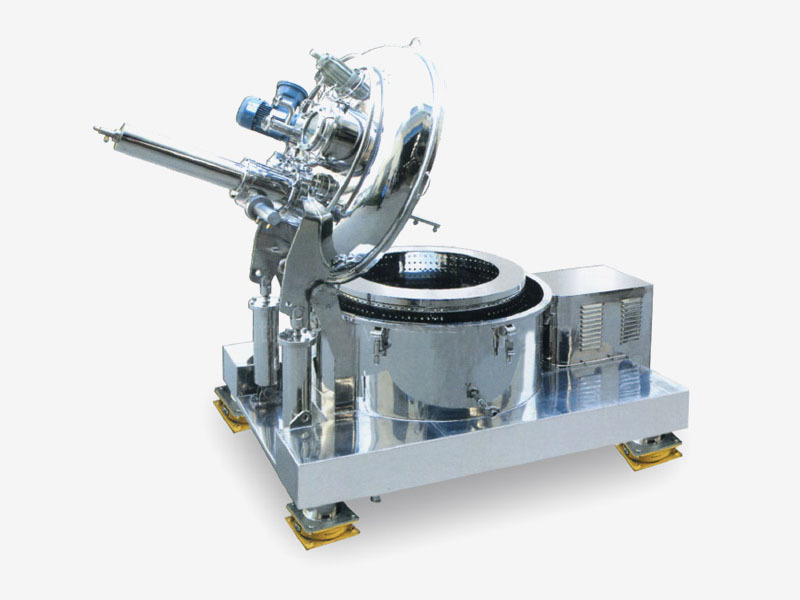

Flat Top Suspension Scraper Discharge Centrifuge

Motor-mounted direct drive, drive and rotary center of the drum coincide with the center of the machine, running smoothly. Liquid damping shock absorber, no foundation installation, easy to operate and maintain.

Contact Us

Classification

Keywords

Centrifuge

Main features

- Motor-mounted direct drive, drive and rotary center of the drum coincide with the center of the machine, running smoothly.

- Liquid damping shock absorber, no foundation installation, easy to operate and maintain.

- Large aspect ratio, large loading volume.

- The shell and the base are rigidly connected with a full bearing structure, and the structure is simple and compact.

- Independent bearing, bearing support span, drum center of gravity is low, large carrying capacity.

- No belt drive, no friction dust.

- Fully automatic operation program control, reliable and safe operation.

- Nitrogen protection device can be configured to realize the application of explosion-proof occasions.

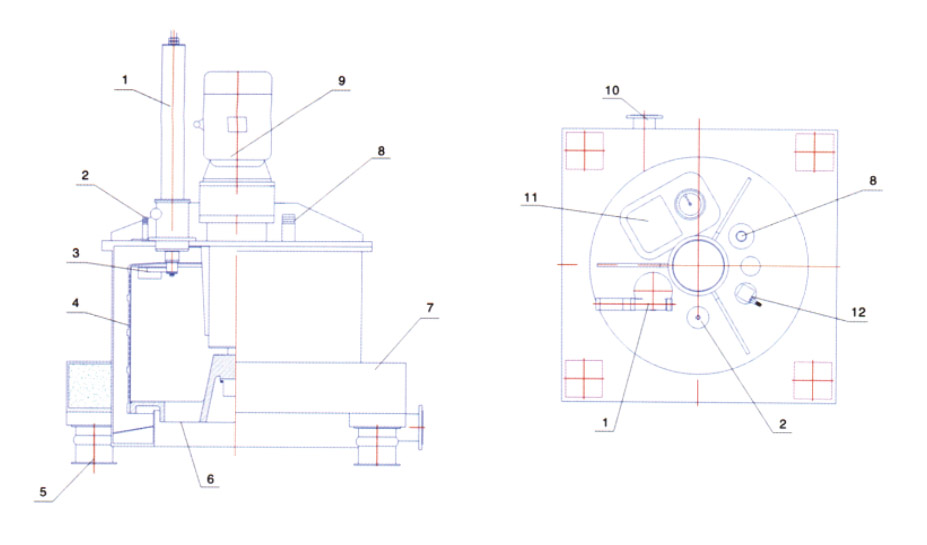

Configuration Description

- Cloth method:Single tube or multi-tube side feeding

- Scraper discharge:Hydraulic

- Motor drive:Ordinary motor, variable frequency motor, explosion-proof motor, energy consumption brake or feedback brake

- Safety protection:Explosion protection, vibration protection, material full detection protection, temperature protection, electromechanical interlock, speed monitoring, overload protection, nitrogen protection system

- Surface treatment:Mirror polishing, matte treatment, passivation treatment

- Electrical components:Brand Supply

- Residual filter cake treatment:Gas blowback, roller-assisted scraper, gas-assisted scraper

- Program control:Programmable control mode, DCS control mode

- Nitrogen protection:Automatic nitrogen supply device, liquid seal device, gas-liquid separator, oxygen content detection system

- Coating treatment:HALAR lining (F30), F40, F46, PFA, PE lining, rubber lining

- Hopper:Caliber and height can be configured according to user requirements

|

|

|

|

|

|

|

|

|

|

|

|

Technical parameters

| Project | PAUT1250 | PAUT1350 | PAUT1500 | PAUT1600 |

| Drum diameter (mm) | 1250 | 1350 | 1500 | 1600 |

| Drum volume (L) | 450 | 500 | 653 | 970 |

| Maximum loading limit (kg) | 610 | 660 | 880 | 1300 |

| Drum speed (r/min) | 970 | 900 | 850 | 850 |

| Separation factor | 658 | 612 | 607 | 647 |

| Motor power (kw) | 30 | 45 | 55 | 75 |

| Overall dimension (LxWxH) (mm) | 2100x2000x2600 | 2100x2100x2600 | 2600x2600x2700 | 2700x2700x2900 |

| Machine weight (kg) | 5000 | 6000 | 8600 | 11000 |