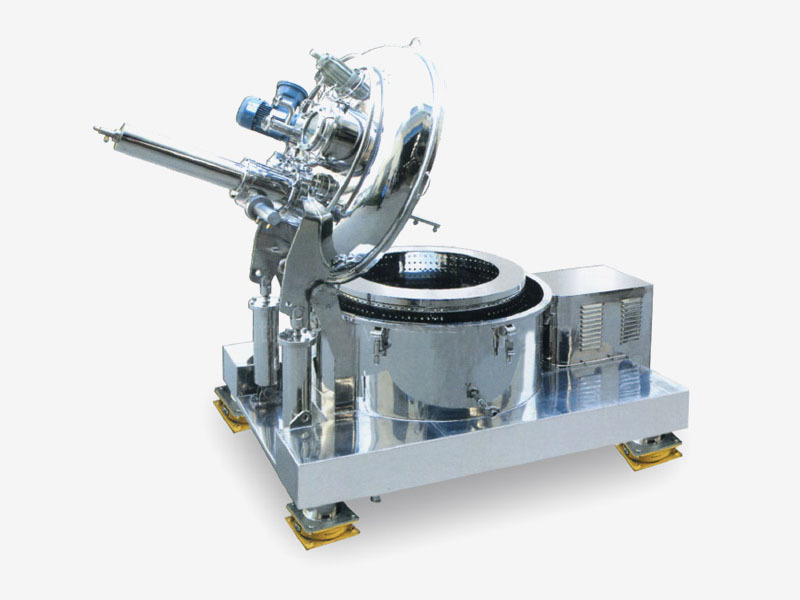

Horizontal Spiral Discharge Filter Centrifuge

Contact Us

Classification

Keywords

Centrifuge

Structure and working principle

LWL series horizontal spiral screen centrifuge is running at full speed, continuous suspension feeding, dehydration, washing, unloading and other process operation of the machine. When the machine is running, first turn on the power supply, the main engine starts and automatically increases the speed. When the predetermined value is reached, the feed valve opens, and the separated material (suspension) enters continuously along the feeding pipe, and passes through several feeding holes on the small end wall of the spiral wheel. Disperse to the drum wall. Under the action of centrifugal force, the liquid phase in the suspension is thrown out through the filter screen and the holes on the drum wall, and discharged outside through the filtrate outlet of the casing, the solid phase is intercepted on the filter screen to form a thin filter residue layer. In the centrifugal force field, because the filter residue has a centrifugal component force pointing to the big end along the generatrix of the rotating drum, and the thrust force pointing to the big end is generated when the spiral blade rotates, these two forces push the filter residue continuously from the small end of the rotating drum to the big end, and the filter residue is continuously turned by the spiral blade in the process of moving, thus greatly strengthening the separation process. The filter residue pushed out of the big end of the drum is discharged out of the machine through the slag discharge port of the casing, realizing solid-liquid separation.

Performance and Usage

LWL series horizontal spiral discharge filter centrifuge is horizontal, continuous work, spiral continuous discharge filter centrifuge. It is mainly used for separation and dehydration of liquid-solid two-phase suspension with solid particle size in the range of 0.05-10mm. Used in chemical, food, chemical fiber, mining and metallurgy, pharmaceutical and light industry and other industries.

Main features

- Continuous operation, spiral discharge, large production capacity.

- The solid phase dehydration rate is high, the washing effect is good, and the separation efficiency is high.

- Compact structure, convenient operation and maintenance.

Main technical parameters

| Item/Model |

LWL250 *200 |

LWL350 *300 |

LWL450 *300 |

LWL530 *350 |

LWL650 *480 |

LWL750 *790 |

LWL800 *500 |

LWL1000 *650 |

LWL1500 *900 |

|

Drum diameter (mm) |

250 | 350 | 450 | 530 | 650 | 750 | 800 | 1000 | 1500 |

|

Drum length (mm) |

200 | 300 | 300/360 | 350 | 480 | 790 | 500 | 650 | 900 |

|

Maximum speed (r/min) |

3800 | 3000 | 2600 | 2000 | 1850 | 2100 | 1500 | 1000 | 800 |

|

Maximum separation factor |

2022 | 1762 | 1702 | 1185 | 1243 | 1848 | 1008 | 560 | 533 |

|

Differential speed between drum and material pushing |

18 | 30 | 30 | 23 | 24 | 23 | 24 | 24 | 24.2 |

| Motor power (kW) | 3 | 15 | 22 | 30 | 45 | 75 | 75 | 90 | 132x2 |

|

Overall dimension (mm) |

940*800 *900 |

1550*1269 *1325 |

1570*1450 *1400 |

1720*1700 *1581 |

1810*1880 *1720 |

2610*2115 *2000 |

2700*2100 *1700 |

3000*2170 *2100 |

4390*2915 *2780 |

|

Machine weight (kg) |

250 | 1450 | 1600 | 2800 | 4000 | 6500 | 6000 | 7600 | 14235 |

| Capacity (m³/h) | 0.5-1.5 | 3-15 | 3-18 | 6-20 | 10-35 | 15-40 | 15-45 | 15-50 | 50-200 |