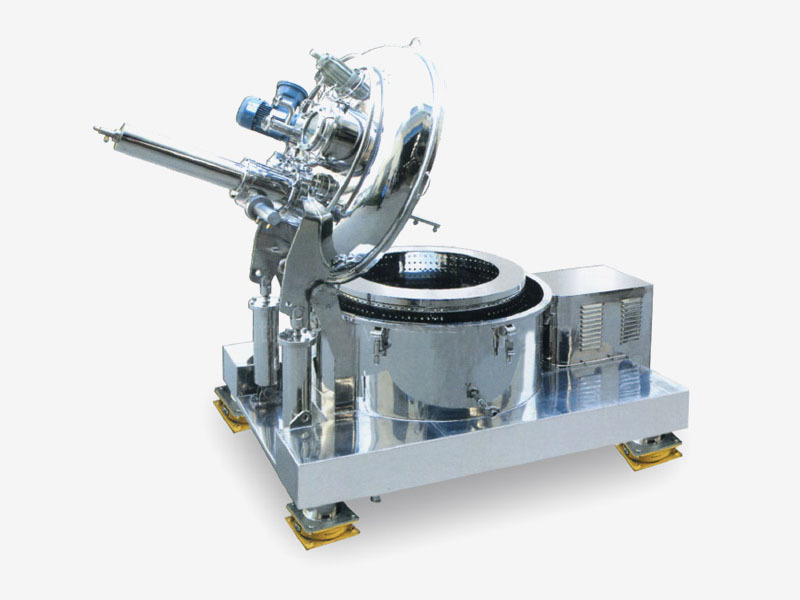

Plate Type Automatic Scraper Lower Discharge Centrifuge

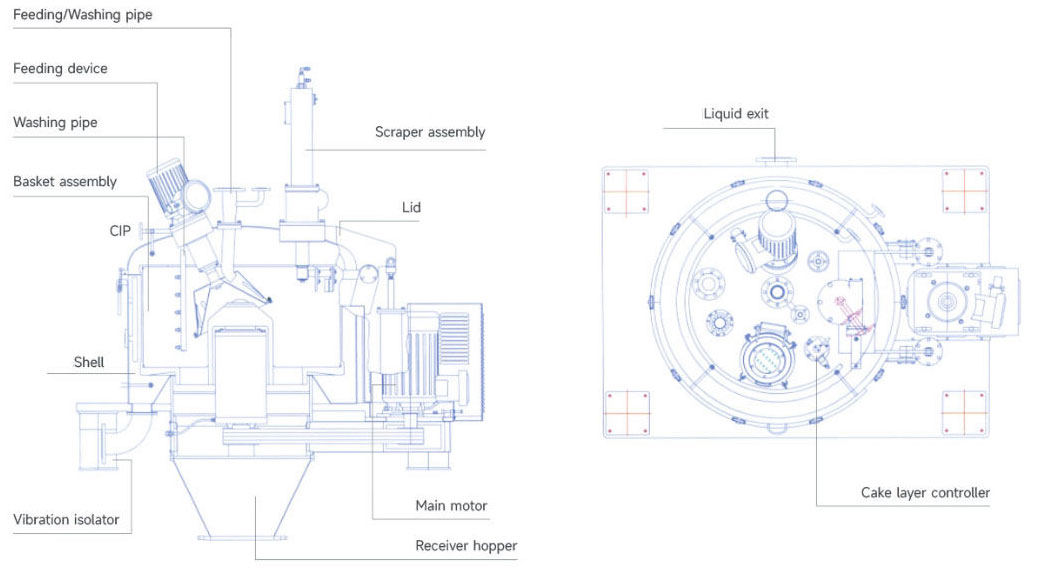

Flat plate structure, low center of gravity of the machine, smooth operation; four-point support, no foundation installation form. Liquid damping vibration reduction, centrifuge vibration isolation and vibration reduction performance is excellent.

Contact Us

Classification

Keywords

Centrifuge

Main features

- Flat plate structure, low center of gravity of the machine, smooth operation; four-point support, no foundation installation form.

- Liquid damping vibration reduction, centrifuge vibration isolation and vibration reduction performance is excellent.

- Independent swash plate cloth device, feeding uniform and controllable.

- Optional nitrogen protection system, can achieve closed explosion-proof requirements, suitable for toxic and flammable and explosive applications. Ensure the safe operation of the machine.

- Large clamshell structure, centrifuge cavity set cleaning device, on-line cleaning of the centrifuge, to avoid cross contamination of products.

- Multiple safety protection devices: over-vibration protection, over-current protection, temperature control protection, material layer control, scraper stroke protection, cover opening protection, mechanical and electrical interlocking protection, various warning and warning signs.

- PLC program control, touch screen, frequency converter control, energy consumption braking, feedback braking, equipment fault self-diagnosis, automatic man-machine interface control, DCS control interface.

- The inner and outer surfaces are polished, and the surface roughness can reach Ra0.2-0.4 μm, which conforms to GMP specifications.

Configuration Selection Description

- Contour structure:Large open cover, full open cover and flat cover structure

- Cloth method:Inclined plate distributor, lateral distribution pipe, intermediate distribution pipe

- Scraper discharge:Hydraulic, pneumatic

- Motor drive:Ordinary motor, variable frequency motor, explosion-proof motor, energy consumption brake or feedback brake

- Safety protection:Explosion-proof, vibration protection, material full detection protection, open cover protection, temperature protection, electromechanical interlocking, speed monitoring, overload protection, nitrogen protection system

- Surface treatment:Mirror polishing, matte treatment, passivation treatment

- Electrical components:Brand Supply

- Residual filter cake treatment:Gas blowback, roller-assisted scraper, gas-assisted scraper

- Program control:Programmable control mode, DCS control mode

- Online cleaning:Cleaning ball, spray pipe

- Nitrogen protection:Automatic nitrogen supply device, liquid seal device, gas-liquid separator, oxygen content detection system

- Coating treatment:HALAR lining (F30), F40, F46, PFA, PE lining, rubber lining

Technical parameters

| Project | LGZ800 | LGZ1000 | LGZ1250 | LGZ1350 | LGZ1600 | LGZ1800 |

|

Drum diameter (mm) |

800 | 1000 | 1250 | 1350 | 1600 | 1800 |

|

Drum volume (L) |

100 | 190 | 400/500 | 500 | 800/1000 | 1000 |

|

Maximum loading limit(kg) |

135 | 255 | 500/600 | 600 | 1000/1200 | 1250 |

|

Drum speed (r/min) |

1200/1500 | 1100/1200 | 1100/1200 | 1000 | 850 | 800 |

|

Separation factor |

645/1008 | 677/805 | 700/1008 | 760 | 647 | 645 |

|

Motor power (kw) |

7.5/11 | 15 | 22/30 | 37 | 37/45 | 55 |

|

Overall dimension (LxWxH) (mm) |

1850*1250*2050 | 2200*1500*2250 |

2550*1800*2550 2550*1800*2900 |

2500*1800*2800 |

3200*2400*3000 3200*2400*3250 |

3500*2500*3400 |

|

Machine weight (kg) |

2000 | 3500 | 5000 | 6000 | 9500 | 15000 |

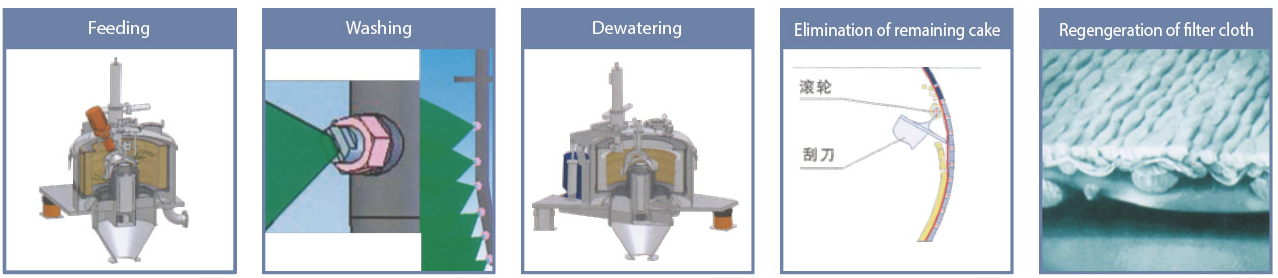

Workflow