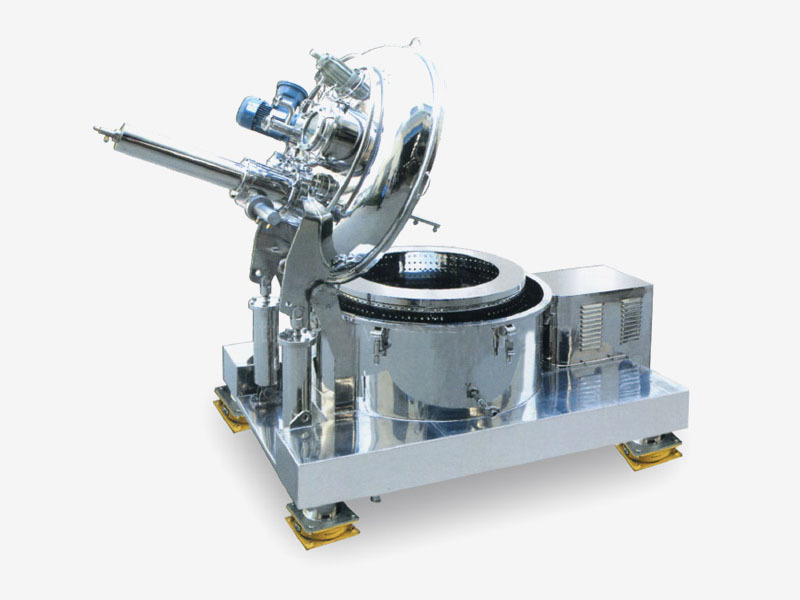

Shake Bag Scraper Lower Discharge Centrifuge

Contact Us

Classification

Keywords

Centrifuge

Main features

- Remove residual filter cake with shaking bag. Through the up and down reciprocating movement of the pneumatic bag shaking device, the residual filter cake of the scraper discharge is completely removed, and the complete discharge and filter cloth regeneration are realized.

- The special design of the drum block liquid plate structure, self-locking and reliable, easy to replace the filter cloth.

- External cylinder connecting rod drive design, reliable work.

- Fully enclosed out of the hopper design, so that the material and transmission parts completely isolated.

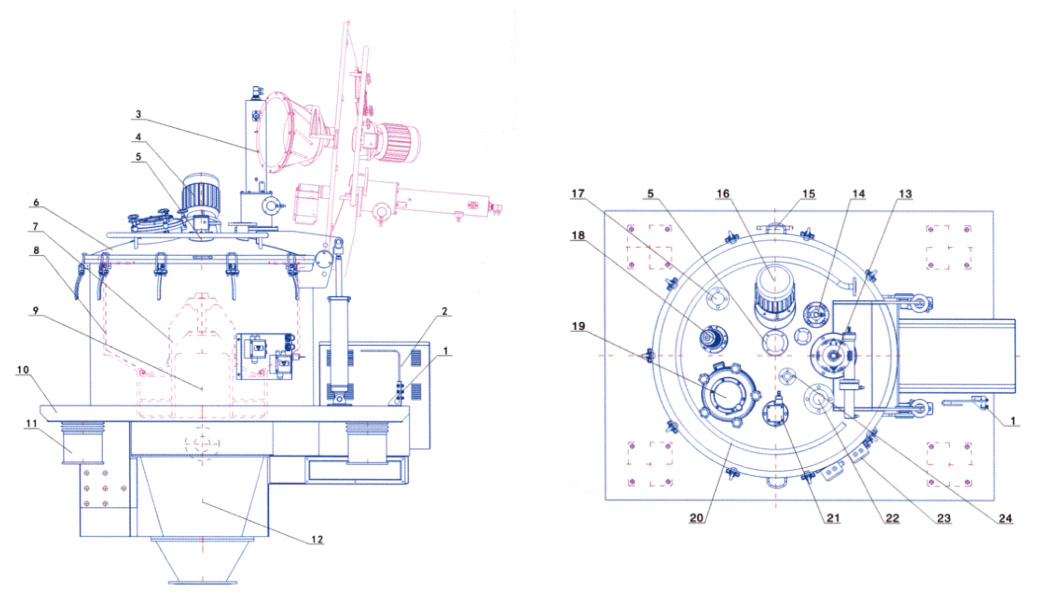

Working principle

The material to be separated is added into the high-speed rotating centrifuge drum through the feed pipe. Under the action of the centrifugal field, the material is filtered through the filter cloth, the liquid phase is discharged through the liquid outlet pipe, and the solid phase is trapped in the drum. When the material is full, the feed is stopped and the filter cake is washed while the washing liquid is filtered off. The centrifuge continues to rotate and dry the filter cake. After the filter cake meets the separation requirements, the centrifuge slows down, and the filter cake is scraped off by a scraper and discharged from the bottom of the machine. The centrifuge reduces the speed again, and the bag pulling device reciprocates to shake off the residual filter cake, so as to realize the complete removal of the filter cake, so as to realize the regeneration of the filter cloth.

Workflow

Configuration Selection Description

- Contour structure:Large open cover, full open cover and flat cover structure

- Cloth method:Inclined plate distributor, lateral distribution pipe, intermediate distribution pipe

- Scraper discharge:Hydraulic, pneumatic

- Motor drive:Ordinary motor, variable frequency motor, explosion-proof motor, energy consumption brake or feedback brake

- Safety protection:Explosion-proof, vibration protection, material full detection protection, open cover protection, temperature protection, electromechanical interlocking, speed monitoring, overload protection, nitrogen protection system

- Surface treatment:Mirror polishing, matted treatment, passivation treatment

- Electrical components:Brand Supply

- Residual filter cake treatment:Removal of residual filter cake by bag shaking device

- Program control:Programmable control mode, DCS control mode

- Online cleaning:Cleaning ball, spray pipe

- Nitrogen protection:Automatic nitrogen supply device, liquid seal device, gas-liquid separator, oxygen content detection system

- Coating treatment:衬HALAR(F30)、F40、F46、PFA

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Technical parameters

|

Project |

LGZD800 |

LGZD1000 |

LGZD1250 |

LGZD1600 |

LGZD1800 |

|

Drum diameter (mm) |

800 |

1000 |

1250 |

1600 |

1800 |

|

Drum volume (L) |

100 |

175 |

400 |

800 |

1250 |

|

Maximum loading limit (kg) |

135 |

235 |

500 |

1000 |

1500 |

|

Drum speed (r/min) |

1200/1500 |

1100/1200 |

1000/1200 |

850 |

800 |

|

Separation factor |

645/1008 |

677/805 |

700/1008 |

647 |

645 |

|

Motor power (kw) |

7.5/11 |

15 |

22/30 |

37 |

55 |

|

Overall dimension (LxWxH) (mm) |

2050x1250x2000 |

2350x1450x2350 |

2550x1800x2550 |

3200x2400x3000 |

3500x2500x3360 |

|

Machine weight (kg) |

2100 |

3550 |

5500 |

11000 |

17500 |