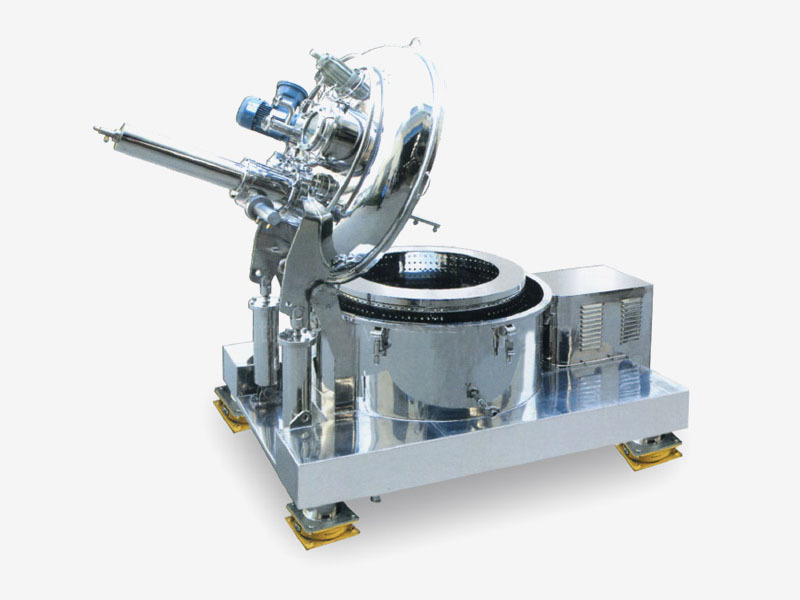

Horizontal Scraper Discharge Centrifuge

Contact Us

Classification

Keywords

Centrifuge

Centrifugation Machine

Product Introduction

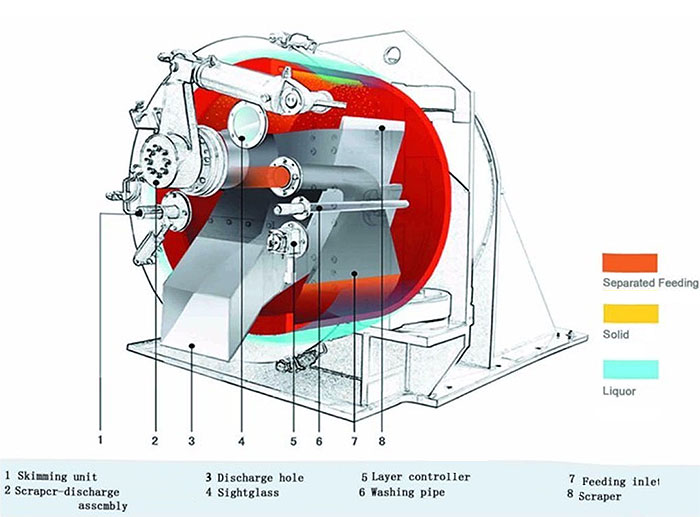

GK horizontal scraper discharge centrifuge is a fully automatic intermittent discharge centrifuge. After the machine is started to the feed speed, the feed valve is opened, and the separated suspension enters the drum through the cloth hopper and is evenly distributed on the filter medium on the inner wall of the drum. Under the action of centrifugal force, the liquid phase is thrown out of the drum through the filter medium and the small holes on the drum, and the solid phase is trapped on the filter medium to form a filter cake. When the filter cake layer reaches the set loading volume, close the feed valve to wash the solid phase, and then spin dry. Finally, the filter cake layer is removed by rotating scraper, and the material is discharged out of the machine in two ways: chute or spiral conveying.

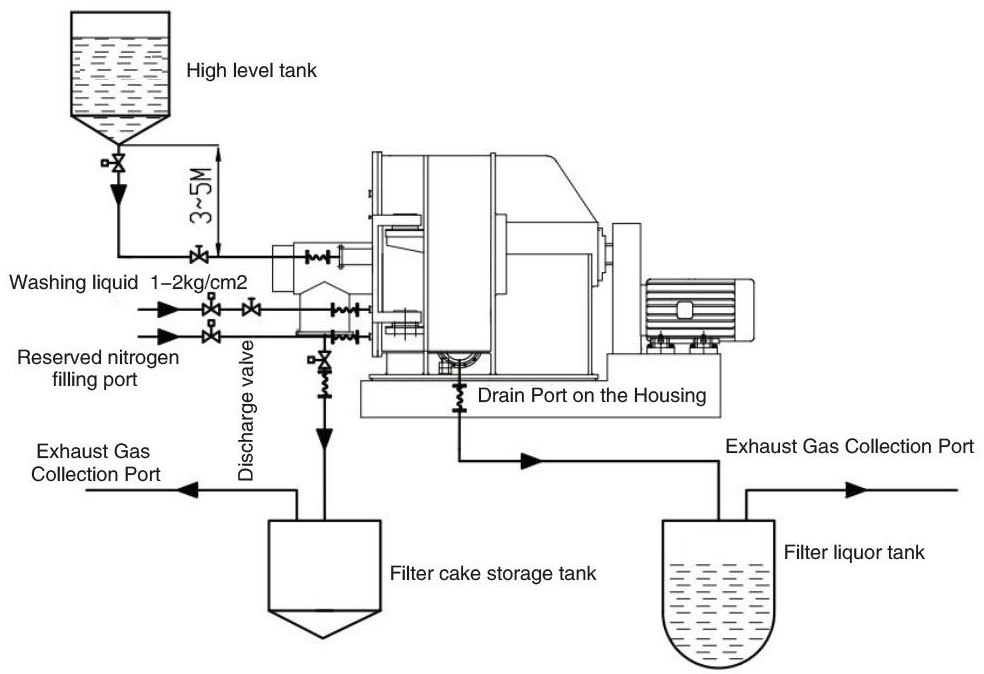

Process Flow Diagram of GK Horizontal Scraper Discharging Centrifuge

Structure, performance characteristics

(1) Automatic operation, manual labor intensity is small;

(2) The implementation of the components of the hydraulic system for automatic control, stable and reliable operation;

(3) Electrical PLC control, accurate action, easy to adjust;

Scope of application

Can be widely used in food, chemical, pharmaceutical, light industry and other industries.

Typical Application Materials

Starch, potassium chloride, salt, heavy alkali, caustic soda, diglycin, sodium cyanide, calcium hydrogen phosphate, ammonium chloride, etc.

Main specifications and technical parameters

| Item/Model | GK800-N | GK1250-N | GK1600-N | GK1600-NB | GK1800-N |

| Drum diameter (mm) | 800 | 1250 | 1600 | 1600 | 1800 |

| Drum length (mm) | 450 | 600 | 800 | 1000 | 1000 |

| Drum speed (r/min) | 1550 | 1200 | 950 | 950 | 815 |

| Loading Limit Weight (kg) | 130 | 400 | 850 | 850 | 1200 |

| Loading volume (L) | 100 | 310 | 680 | 830 | 1112 |

| Separation factor | 1070 | 1006 | 800 | 800 | 815 |

| Main motor power (kW) | 37/30 | 55 | 110 | 110 | 132 |

| Overall dimension (mm) | 2450×1700×1300 | 3100×2100×1800 | 3900×2700×2300 | 3900×2700×2300 | 5800×2850×2620 |

| Machine weight (kg) | 3500 | 7500 | 12500 | 13000 | 25000 |

A centrifugation machine is a critical laboratory and industrial device designed to separate components of a mixture based on differences in density. Utilizing rapid rotational motion, the machine generates centrifugal force that drives denser particles outward, while lighter components remain closer to the center. This process allows efficient separation of liquids, solids, and suspensions, making centrifugation machines indispensable in a wide range of applications including clinical diagnostics, pharmaceutical production, chemical processing, food and beverage clarification, wastewater treatment, and research laboratories.

In medical and clinical laboratories, centrifugation machines are essential for processing blood, urine, and other biological samples. Whole blood, for example, can be separated into plasma, serum, and cellular components, facilitating diagnostic testing, blood transfusions, and research. In pharmaceutical and biotechnology industries, centrifuges are used for isolating cells, proteins, nucleic acids, and other biomolecules, providing high-purity samples necessary for drug development, quality control, and analytical testing. Industrial centrifuges help clarify liquids, dewater sludge, and separate chemical suspensions, enhancing process efficiency and product quality. In the food industry, centrifugation machines are applied to clarify juices, milk, oils, and other beverages, ensuring smooth and consistent products.

Modern centrifugation machines are equipped with programmable speed controls, adjustable timers, and temperature regulation systems to ensure precise and reproducible results. Refrigerated centrifuges maintain sample integrity for temperature-sensitive materials during high-speed operation. Safety mechanisms such as imbalance detection, lid locking systems, and emergency stop functions protect both the operator and the equipment, preventing accidents and ensuring stable operation. The versatility of centrifugation machines allows them to accommodate a wide range of sample volumes and types, from small benchtop models for laboratory use to large-scale industrial units for continuous processing.

Rotor design is a key factor in the efficiency of a centrifugation machine. Fixed-angle rotors hold sample tubes at a constant angle, promoting rapid sedimentation of solids, while swinging-bucket rotors allow tubes to move outward during rotation, providing even separation of layered components. Ultracentrifuges operate at extremely high rotational speeds, generating forces thousands of times stronger than gravity, which is critical for separating microscopic particles, viruses, organelles, and macromolecules in molecular biology, nanotechnology, and biomedical research. Proper maintenance, including regular cleaning, rotor inspection, and calibration, ensures long-term performance and safety. Operator training is essential for correct sample handling, balanced loading, and adherence to safety protocols.

Overall, centrifugation machines play an indispensable role in scientific research, healthcare, industrial processing, and quality control. By combining precision engineering, robust construction, and user-friendly operation, they enable efficient separation, higher sample quality, and faster workflow. Their versatility, reliability, and performance make centrifugation machines essential equipment in laboratories, production facilities, and industrial plants worldwide, supporting innovation, efficiency, and consistent results across multiple sectors.