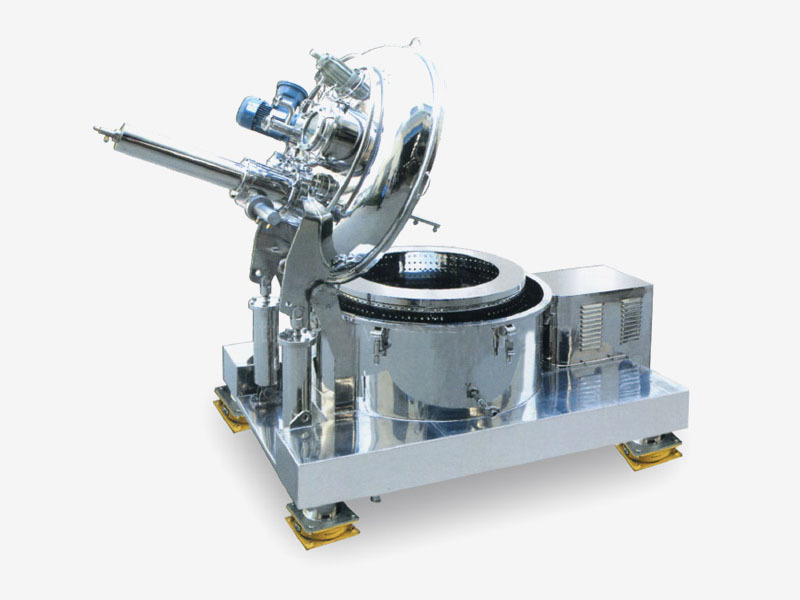

Plate-Type Artificial Upper Discharge Centrifuge

Structure transition smooth, the surface by polishing treatment, effectively eliminate the health dead, and material contact part of the material made of stainless steel. The flip cover can be opened to effectively clean the space between the centrifuge shell and the drum.

Contact Us

Classification

Keywords

Centrifuge

Main features

- The welding position of the structural part is arc transition, all stainless steel surfaces are polished to eliminate sanitary dead ends, and the material contact part is made of stainless steel.

- The machine cover can be opened to effectively clean the space between the centrifuge shell and the rotating drum. The opening of the cover can be configured with manual flip cover or hydraulic and pneumatic automatic flip cover.

- Flat plate structure, lower the center of gravity of the machine, the base plate can be used as an operating platform.

- Equipped with liquid damping shock absorber, the vibration reduction efficiency is high.

- The machine cover is provided with feeding pipe, washing pipe, observation mirror and illumination hole. Optional online cleaning system, the inner wall of the centrifuge shell, the inner and outer surfaces of the drum, the surface of the sump and other invisible parts of the centrifuge cleaning, in line with GMP specifications.

- The grains are not easy to break, and can be used for the separation of solid-phase granular suspensions, and can also be used for the separation of fibrous materials, with a wide range of applications.

- The inverter starts, starts smoothly, and the separation factor is adjustable.

- Closed structure, the seal is made of silicone rubber or fluorine rubber, etc., and the optional nitrogen protection system can achieve the requirements of closed explosion-proof, suitable for the application of toxic and flammable and explosive occasions.

- Direct explosion-proof motor can be used to eliminate the friction dust generated by belt drive; at the same time, because the motor is installed at the bottom of the machine, the centrifuge covers a smaller area.

PSB Technical Parameters

| Project | PSB600 | PSB800 | PSB1000 | PSB1200 | PSB1250 | PSB1500 |

|

Drum diameter (mm) |

600 | 800 | 1000 | 1200 | 1250 | 1500 |

| Drum volume (L) | 45 | 120 | 200 | 330 | 400 | 600 |

|

Maximum loading limit (kg) |

60 | 150 | 250 | 410 | 500 | 800 |

|

Drum speed (r/min) |

1500 | 1200/1500 | 1100/1200 | 1100/1200 | 1000/1200 | 850 |

| Separation factor | 755 | 645/1006 | 680/806 | 670/968 | 700/1008 | 607 |

|

Motor power (kw) |

3 | 7.5 | 11 | 18.5 | 18.5/22 | 30 |

|

Overall dimension (LxWxH) (mm) |

1300*1050*1150 | 1700*1200*1300 | 2000*1400*1500 | 2550*1800*1750 | 2550*1800*1750 | 2600*2300*1800 |

|

Machine weight (kg) |

1100 | 1500 | 2500 | 3800 | 3800 | 6000 |

PBZ Technical Parameters

| Project | PBZ300 | PBZ450 | PBZ600 | PBZ800 | PBZ1000 |

| Drum diameter (mm) | 300 | 450 | 600 | 800 | 1000 |

| Drum volume (L) | 5 | 20 | 40 | 100 | 155 |

|

Maximum loading limit (kg) |

7 | 30 | 55 | 135 | 200 |

| Drum speed (r/min) | 2825 | 1900 | 1500 | 1200 | 1000 |

| Separation factor | 1340 | 910 | 755 | 645 | 560 |

| Motor power (kw) | 11 | 1.5 | 3 | 5.5 | 7.5 |

|

Overall dimension (LxWxH) (mm) |

600*600*850 | 850*850*1000 | 1200*1050*1300 | 1500*1250*1400 | 1600*1400*1450 |

| Machine weight (kg) | 200 | 300 | 1100 | 1500 | 2000 |