Mechanical Pusher Centrifuge

Contact Us

Classification

Keywords

Centrifuge

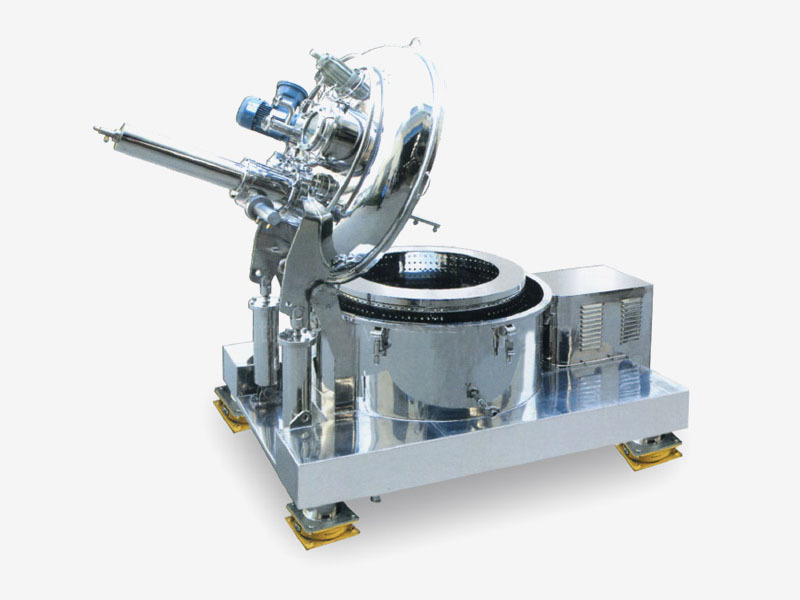

Mechanical Pusher Centrifuge

Structure and principle

- PM series mechanical two-stage pusher centrifuge. It is mainly supported on the base by the reducer, pushing mechanism, machine base, bearing combination, drum, screen, casing and parts through bearing combination.

- Compared with the traditional piston pusher centrifuge, the model cancels the hydraulic drive structure and uses the mechanical crank slider mechanism as the drive.

- The rotating body is connected with the main motor pulley through a triangular tape. The electric cabinet is a separate system, installed in a position suitable for the host.

- The main engine is running at full speed, and the suspension enters the distribution plate installed on the outer drum through the feed pipe. Under the action of the centrifugal force field, the suspension is evenly distributed on the plate net in the drum. The liquid phase leaks out through the plate gap of the plate mesh and the filter holes of the rotary drum, while the solid phase is trapped on the plate mesh to form an annular filter residue layer. Through the reciprocating motion of the inner drum, the filter residue moves along the axial direction of the drum and is discharged through the collecting trough in front of the outer drum.

Main features

- Crank slider type mechanical drive, high transmission efficiency, more energy-saving under the same capacity conditions.

- No hydraulic oil drive, the site environment clean.

- The entire operation process is fully automatic and continuous without manual intervention.

- Complete at full speed, such as feeding, separation, washing, drying and unloading processes.

- Suitable for the separation of crystalline or short fiber-like concentrated suspensions containing medium particles.

- The grain is not easy to break, filter residue can be washed.

- Large capacity, high recovery rate, low moisture content of filter residue, low energy consumption.

- Have invention patents, reliable quality.

- The number of pushing materials can be adjusted, which can better adapt to the needs of process changes.

Typical applications

Sea salt, well mineral salt, mirabilite, sodium sulfate, coking ammonium sulfate, flue gas desulfurization ammonium sulfate, wastewater sodium chloride, wastewater sodium sulfate, gelatin, urotropine, ferrous sulfate, p-xylene, ammonium chloride, acrylamide, sodium dichromate, boric acid, acetate fiber, nitrocellulose, caustic soda, potassium chloride, potassium sulfate, potassium carbonate, phosphate

Model and main technical parameters

|

Item/Model |

PM230-N |

PM260-N |

PM300-N |

PM420-N |

|

Inner diameter of drum (mm) |

190/230 |

220/260 |

290/360 |

357/420 |

|

Length of filtration area (mm) |

120/120 |

140/140 |

180/180 |

180/180 |

|

Drum speed (r/min) |

0-3600 |

0-3200 |

0-2500 |

0-2000 |

|

Separation factor |

0-1668 |

0-1490 |

0-1180 |

0-940 |

|

Pusher stroke (mm) |

40 |

40 |

50 |

50 |

|

Pusher times (min-1) |

30-90 |

30-90 |

30-80 |

30-80 |

|

Main motor power (KW) |

3-5.5 |

4-7.5 |

11 |

15 |

|

Motor power of oil pump (KW) |

3 |

3 |

5.5 |

7.5 |

|

Processing capacity (t/h) |

0.05-0.2 |

0.1-0.3 |

1.5-2 |

2-3 |

|

Net weight of machine (kg) |

800 |

850 |

2200 |

2400 |

|

Overall dimension (mm) |

1653×1150×715 |

1675×1150×715 |

2200×1280×1105 |

2260×1290×1135 |

The Mechanical Pusher Centrifuge represents a significant advancement in continuous solid-liquid separation technology, offering a robust and efficient solution for a wide range of industrial applications. Its primary advantage lies in its ability to handle large volumes of feed slurry continuously, unlike batch centrifuges which require cyclic stopping and starting.

This continuous operation is the cornerstone of its high-capacity performance, making it exceptionally suitable for processes where a constant, uninterrupted flow of material is essential for overall plant productivity. The fundamental working principle of a Mechanical Pusher Centrifuge involves a feeding system that introduces the slurry onto a rotating perforated basket.

The centrifugal force immediately drives the liquid through the screen, while the solids form a cake on the basket wall. A reciprocating pusher plate then systematically advances this cake across the basket length, eventually discharging the dewatered solids out of the machine. This elegant and mechanically straightforward action is what allows for its remarkable continuous processing capability.