Ksz Gypsum Special Dewatering Machine

Contact Us

Classification

Keywords

Centrifuge

Gypsum Dewatering Machine

KSZ gypsum special dewatering machine for desulfurization gypsum dehydration

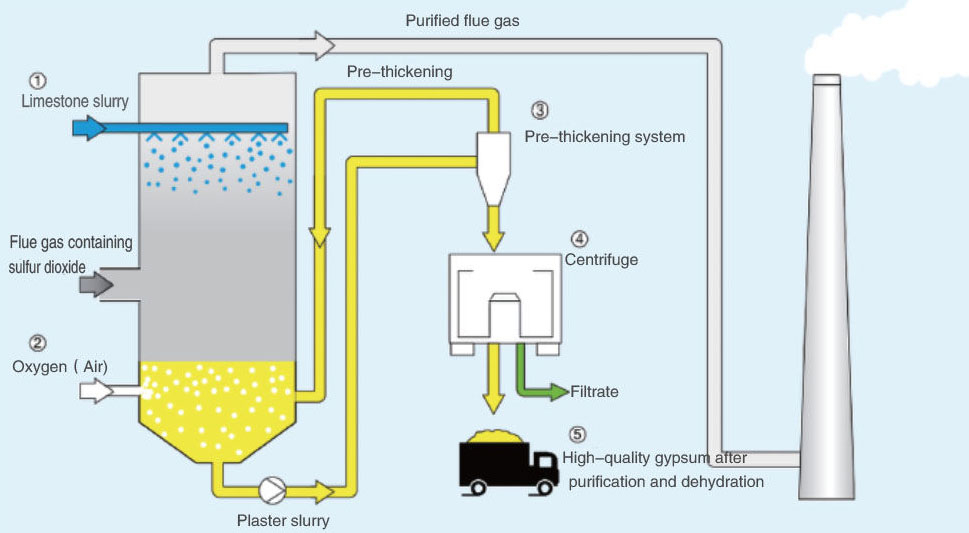

FGD wet flue gas desulfurization technology is usually used in thermal power plants, garbage burning plants, cement plants and other products due to the production of sulfur dioxide desulfurization treatment process. The gypsum produced by the FGD process can be separated from the mother liquor by a special gypsum dehydrator and cleaned. The finished product can be used to make gypsum board for construction and special gypsum board (sound insulation board, etc.) or as additives and filling materials.

KSZ gypsum special dewatering machine for titanium gypsum dehydration

The production of titanium dioxide by sulfuric acid method produces a large amount of acidic wastewater (containing ~ 2% sulfuric acid). The addition of lime (or carbide slag) is used to neutralize the acidic wastewater to produce titanium gypsum with gypsum dihydrate as the main component. Now China's annual emissions of titanium gypsum has reached more than 1000 million tons. At present, the vast majority of titanium gypsum using slag yard storage has caused a huge waste of resources and environmental pollution. The comprehensive utilization of titanium gypsum is imminent. The method of producing white gypsum and red gypsum for cement retarders and building materials is widely used, and the dehydration of gypsum becomes a key step in this production process.

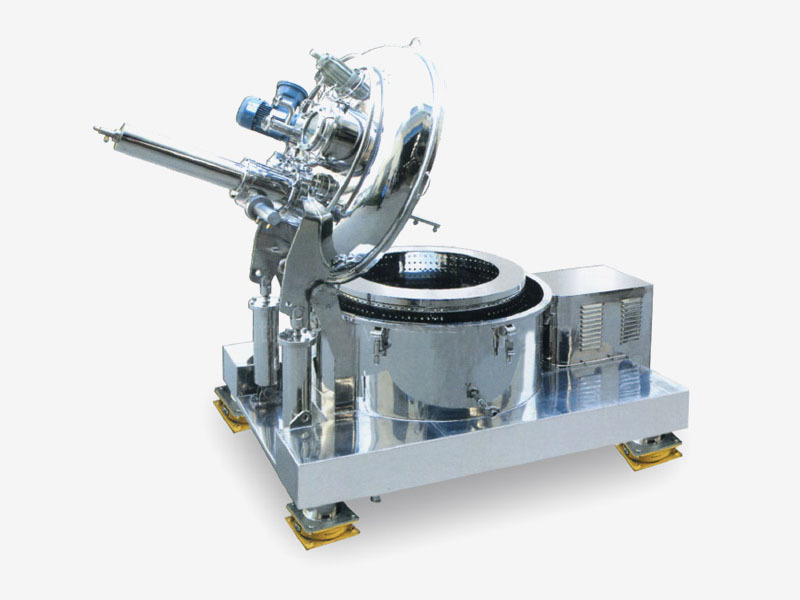

Xiangtan Huibo Centrifuge Co., Ltd.'s KSZ series gypsum dewatering machine can achieve its highest efficiency in long-term production, even under extremely abnormal working conditions. Its high output and excellent separation performance ensure the maximum dehydration capacity of gypsum slurry.

Titanium dioxide production waste acid neutralization process

Wet flue gas desulfurization process

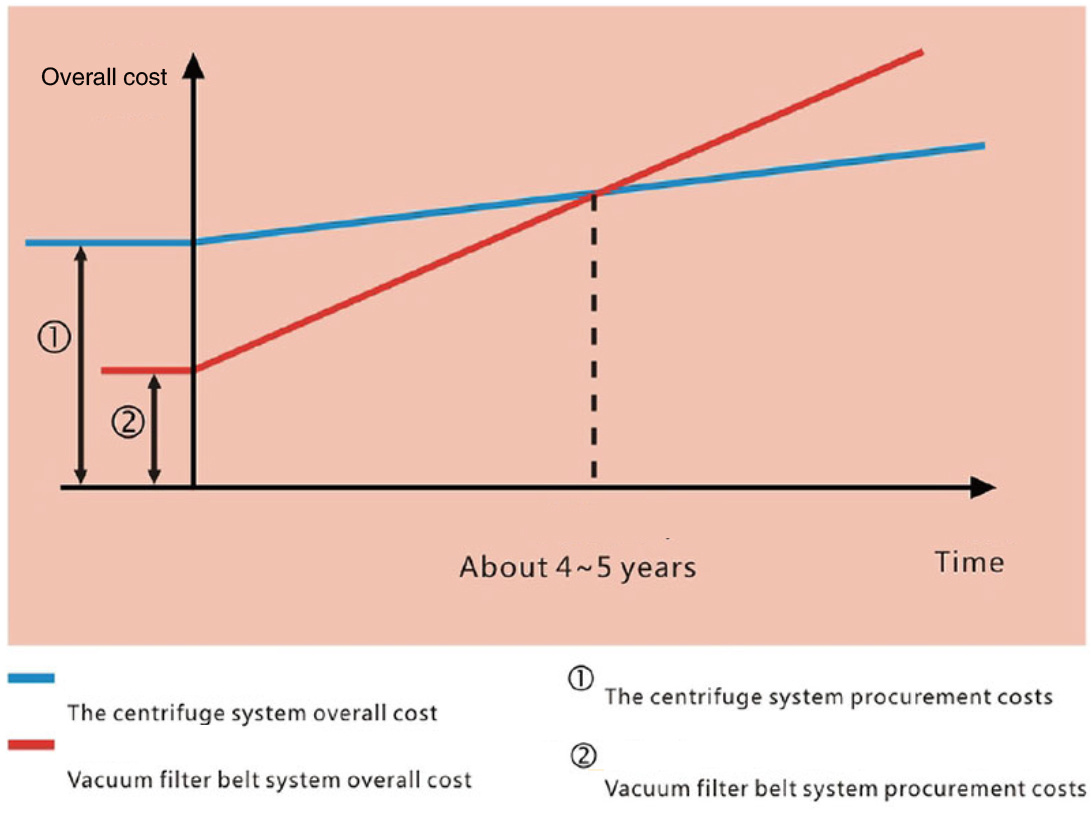

The obvious cost advantage of gypsum dehydrator over belt filter

- Low energy consumption and low energy costs. Only in the short time of feeding and acceleration need to play the full power of the motor, the other time in low power operation.

- The amount of flushing liquid is small, which reduces the cost of water.

- The footprint is small (about 2/3 less than the vacuum filter belt) and the construction cost is significantly reduced.

- Fully enclosed dewatering machine system, operate more clean, reduce the cost of related equipment.

- Reduced maintenance and maintenance costs (e. g. no need to maintain vacuum pumps, etc.)

KSZ gypsum special dewatering machine for gypsum treatment

High quality products

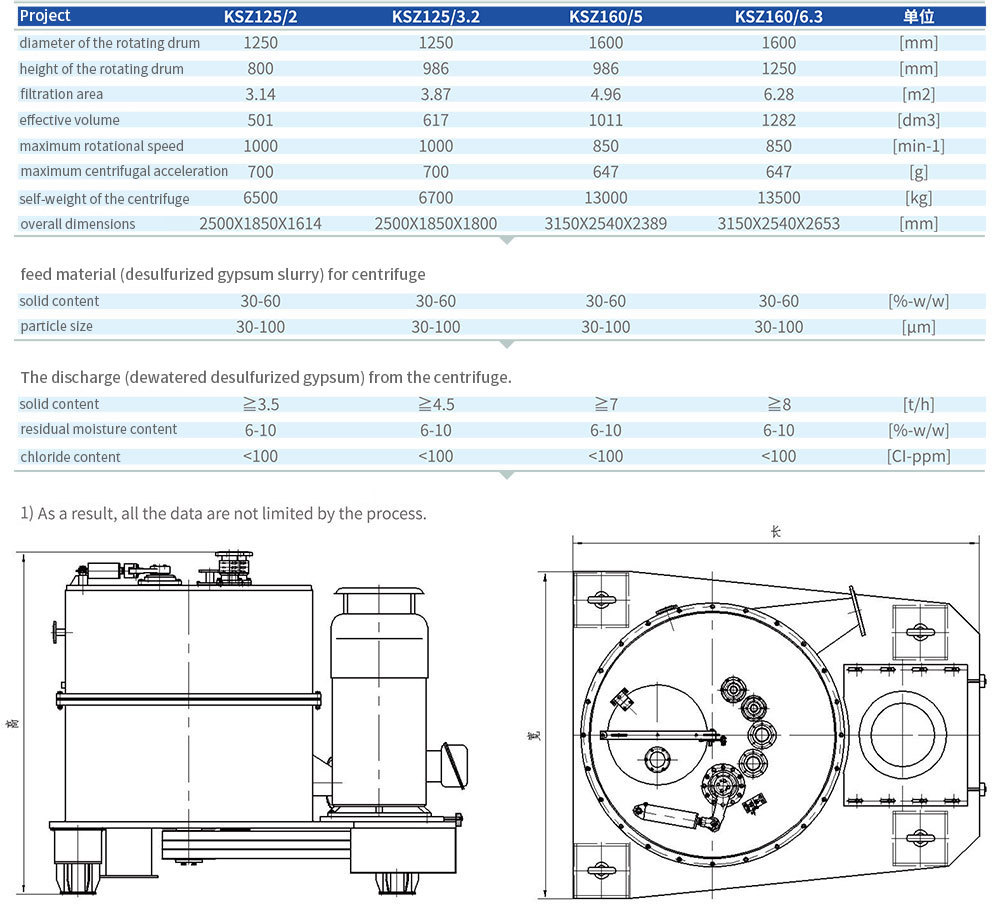

The flushing efficiency is high, the gypsum contains low chlorine gas (less than 100ppm), and the product purity is high.

High solid-liquid separation efficiency, low residual moisture content of gypsum (6-10% w/w)

Environmental protection

The fully enclosed dehydrator system makes the working environment cleaner and has low noise (<85dB).

Finished desulfurization gypsum can be used in construction and other industries, rather than piling up in landfills to cause secondary environmental pollution.

The concept of energy, water, maintenance costs and environmental protection has been paid more and more attention, and the Gypsum Dehydrator has advantages in these aspects.

Cost comparison between dehydrator and vacuum filter belt

Compared with the vacuum filter belt, the purchase cost of the dehydrator system is slightly higher, but the failure rate of the dehydrator is low, which avoids unnecessary losses. Low operating costs (maintenance, energy consumption, etc.). Long service life. After 4-5 years of operation, the total cost of the dehydrator system is much lower than that of the vacuum filter belt

Main parameters of centrifuge

Gypsum dewatering machine, efficiently separating water from gypsum slurry to enhance drying, handling, and overall production efficiency.