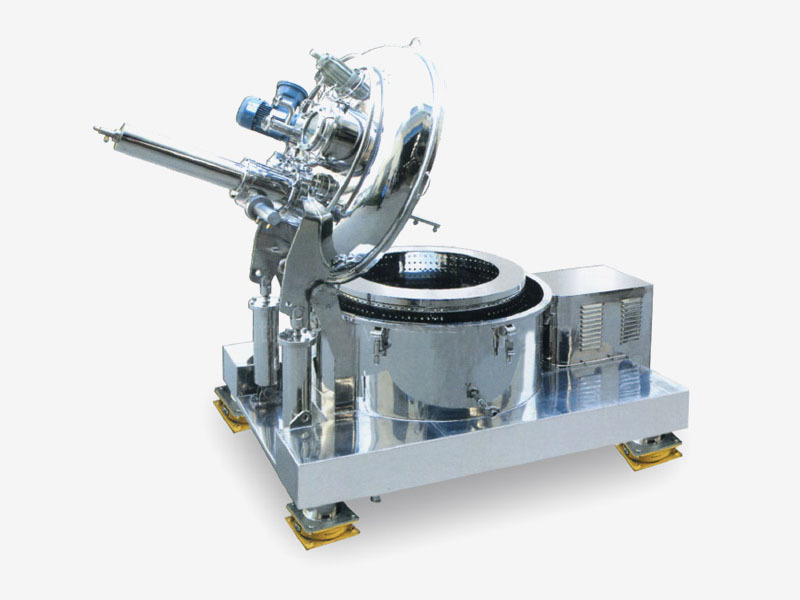

Horizontal Concentration Filter Centrifuge

Contact Us

Classification

Keywords

Centrifuge

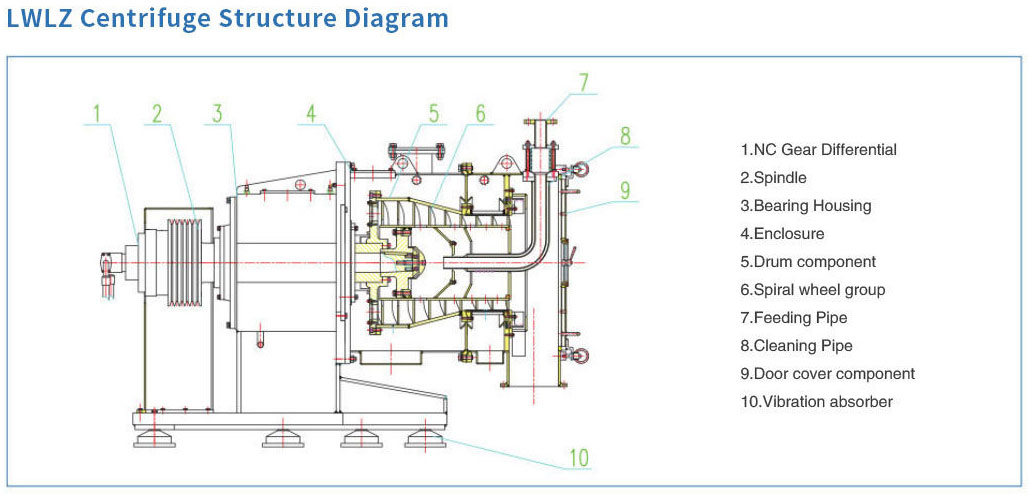

Product Principle

LWLZ series horizontal spiral discharge sedimentation filtration centrifuge is a combined spiral discharge centrifuge. The centrifuge drum is designed with sedimentation section and filtration section. The screw conveyor is used to transport the filter residue unloading. When the machine is running, the drum and the screw conveyor rotate in the same direction and have a certain speed difference. The separated suspension flows to the distribution bin in the screw conveyor through the feed pipe, the distribution cone in the distribution bin is used to accelerate the material into the sedimentation section of the centrifuge drum, and the slurry is concentrated by the principle of centrifugal sedimentation. The clarified liquid produced in the concentration process is discharged through an overflow device with adjustable liquid level on the back side, and the thickened solid phase material is conveyed to the filtration section equipped with a screen through the screw for further dewatering, thus, solid phase recovery with extremely low water content is obtained. The washing device provided by the machine can wash the filter residue in the filter section. The filtrate produced in the settling section and the filtration section is collected separately, and if necessary, the washing liquid and the mother liquor of the filtration section can also be collected separately.

Typical applications

Crystals, particles or fibers with good settling properties Particle size greater than 0.05mm

The concentration of solid feed into the centrifuge is 0-60wt% (wt%: percentage by weight)

Main advantages

- Long life of basket parts

- High yield (small solid loss)

- High dryness of finished product

- The cantilever design can meet:

- The screen is easy to replace, no need to disassemble the spiral

- Simple design of sealing device

Main technical parameters

|

Item/Model |

LWLZ450 |

LWLZ530 |

LWLZ650 |

LWLZ900 |

LWLZ1200 |

|

Drum diameter (mm) |

450 |

530 |

650 |

900 |

1200 |

|

Drum length (mm) |

500 |

590 |

670 |

1000 |

1200 |

|

Maximum speed (r/min) |

2800 |

2000 |

1800 |

1500 |

1100 |

|

Maximum separation factor |

1970 |

1186 |

1140 |

1130 |

812 |

|

Differential speed between drum and material pushing |

10-45 |

10-40 |

0-50 |

5-30 |

0-50 |

|

Motor power (kW) |

22/11 |

45 |

55 |

90 |

132 |

|

Overall dimension (mm) |

2170x1445x1350 |

2450x1700x1500 |

2590x2100x1600 |

3180x2580x1890 |

3990x2780x2130 |