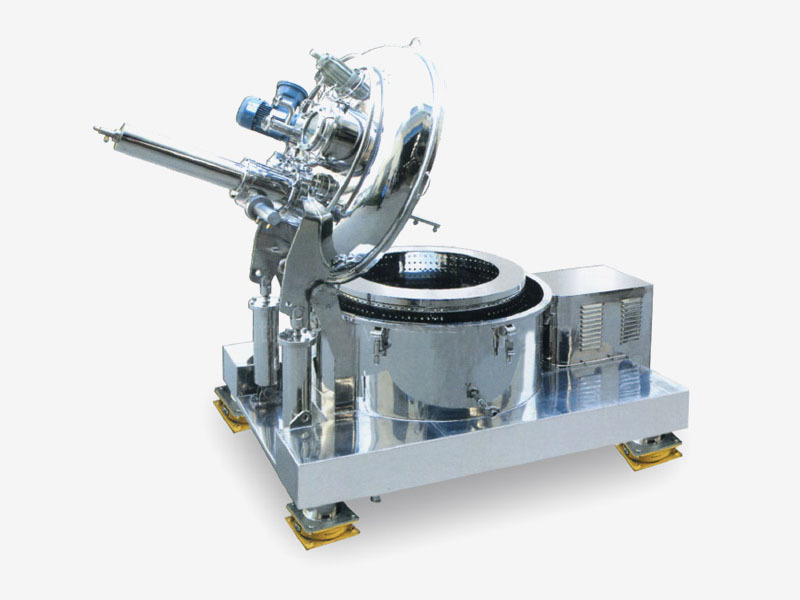

Horizontal Two-Stage Piston Pusher Centrifuge

Contact Us

Classification

Keywords

Centrifuge

Horizontal Centrifuge

Working principle

HR series two-stage piston pusher centrifuge is a continuous operation of the filter centrifuge. Feeding, deliquouring, washing, drying and discharging were done at full speed. It is suitable for separating crystalline or short fiber materials with particle size (particle size) of 0.05mm ~ 5mm and suspension concentration (solid volume ratio) of 30% ~ 80%, especially suitable for materials that need to be washed in the machine.

Structure, performance characteristics

(1) Automatic continuous operation, low labor intensity;

(2) Compact structure, small footprint, easy installation and maintenance;

(3) Large production capacity and low moisture content of filter cake;

(4) Uniform cloth, small vibration;

(5) The filter cake can be washed;

(6) Can prevent grain breakage.

Scope of application

Widely used in chemical, fertilizer, salt, alkali, pharmaceutical, food, light industry and other industries.

Typical application materials are

Sodium chloride, potassium chloride, ammonium chloride, potassium sulfate, sodium sulfate, Glauber's salt, ammonium sulfate, potassium carbonate, sodium hydroxide, nitrocellulose, acetate, potassium dihydrogen phosphate, hrotropine, and other sulfates, carbonates, nitrates, phosphates, etc.

Main specifications and technical parameters

Item/Model | HR260-NB | HR400-NB | HR420-NB | HR500-NB | HR530-NB | HR630-NB | HR800-NB | HR1000-NB | HR1250-NB |

Inner diameter of drum(mm) | 220/260 | 337/400 | 357/420 | 438/500 | 468/530 | 560/630 | 720/800 | 920/1000 | 1180/1250 |

Filtration zone length(mm) | 120/120 | 160/160 | 160/160 | 180/180 | 180/180 | 240/240 | 300/300 | 360/360 | 400/400 |

Drum speed (r/min) | 1800-2800 | 1400-2300 | 1400-2300 | 1200-2000 | 1000-2000 | 1000-1800 | 800-1600 | 850-1200 | 800-1000 |

Separation factor | 507-1228 | 400-1180 | 426-1243 | 400-1120 | 296-1186 | 350-1140 | 290-1150 | 405-1612 | 447-699 |

Pusher stroke (mm) | 40 | 50 | 40 | 50 | 50 | 50 | 50 | 70 | 70 |

Number of material pushing (min-1) | 30-50 | 30-80 | 30-80 | 30-80 | 30-80 | 30-80 | 30-80 | 30-80 | 30-80 |

Main motor power(kW) | 7.5 | 11 | 15 | 37-45 | 37-45 | 45-75 | 55-90 | 90-132 | 110-160 |

Motor power of oil pump (kW) | 4 | 5.5 | 7.5 | 22 | 22 | 30 | 37-45 | 55-75 | 75-90 |

Processing capacity (t/h) conditions) | 0.5-1 | 2-2.5 | 2-2.5 ammonium sulfate) | 12-18 | 12-20 | ≥ 30 (table salt) | ≥50 | ≥70 (table salt) | ≥90 (table salt) |

Net weight of machine (kg) | 1550 | 1945 | 1960 | 4200 | 4500 | 4860 | 6200 | 13000 | 19000 |

Overall dimension (mm) | 1870*860 *640 | 2530*1290 *1155 | 2530*1290 *1155 | 3365*1330 *1628 | 3365*1330 *1628 | 3130*1840 *1265 | 3650*1880 *1610 | 3850*2160 *1980 | 4250*2260 *2180 |

Horizontal centrifuge, engineered for fast and efficient separation of solids and liquids in industrial and laboratory applications.