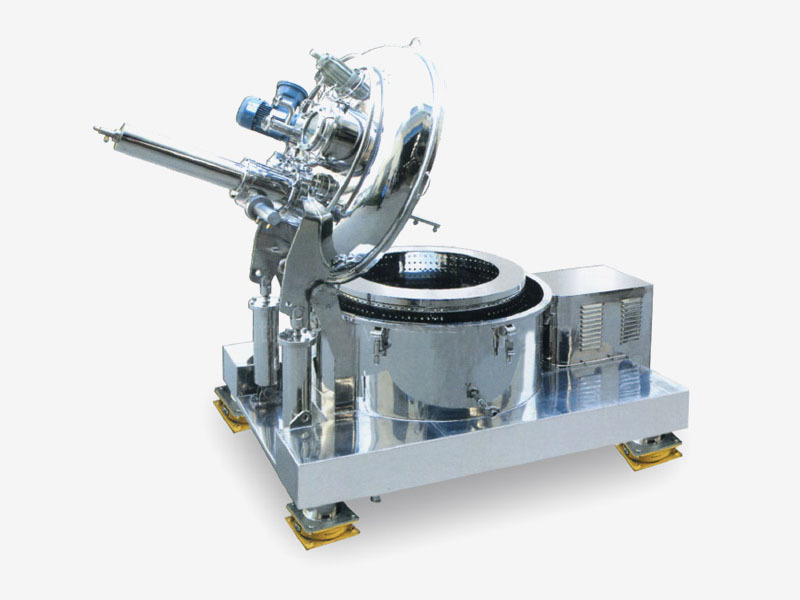

Disc Separator

Contact Us

Classification

Keywords

Centrifuge

Model, basic parameters and application of Huibo dish separator

DBX330-3, DBX440-3, DBX550-3, DBX640-3, DBX730-3, DBX785-3 three-phase disc separators

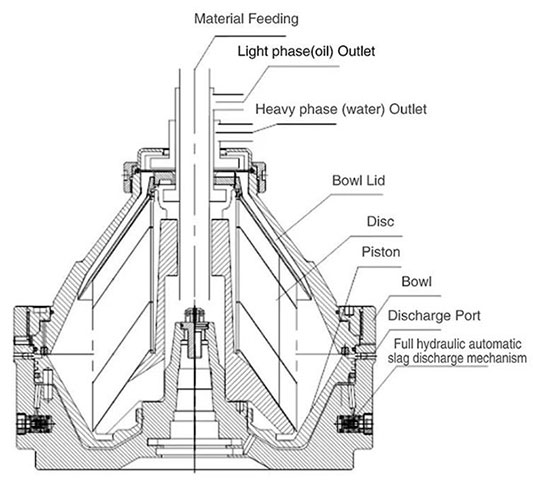

This machine is a disc piston automatic slag discharge drum with inner diameters of 330mm, 440mm, 550mm, 640mm, 730mm, 785mm liquid solid three-phase disc separator. The internal structure of X will vary according to different industries and materials used,

This machine is mainly used for the separation of oil-water materials with low solid content (generally less than 2%), such as milk defatting, separation of animal and vegetable oils, extraction of biochemical and pharmaceutical drugs, and degreasing of environmentally friendly wastewater.

Basic parameters of three-phase separator

|

Model |

DBX330-3 |

DBX440-3 |

DBX550-3 |

DBX640-3 |

DBX730-3 |

DBX785-3 |

|

Inner diameter of drum mm |

330 |

440 |

550 |

640 |

730 |

785 |

|

Water flow t/h |

4 |

7 |

12 |

20 |

30 |

50 |

|

Working speed rpm |

8500 |

6900 |

6000 |

5300 |

4800 |

4200 |

|

Separation factor (g) |

≥ 12000 |

≥ 10000 |

≥ 9800 |

≥ 9000 |

≥ 8800 |

≥ 7700 |

|

Installed power kW |

7.5 |

15 |

30 |

45 |

55 |

90 |

|

Overall dimension (length◊width◊height) mm |

1150◊850◊1200 |

1280◊1250◊1550 |

1720◊1300◊1900 |

1850◊1450◊1980 |

2155◊1750◊2000 |

2555◊2250◊2300 |

|

Net weight kg |

680 |

1150 |

2250 |

2700 |

4000 |

6000 |

The processing capacity varies according to the different materials, welcome the professional and technical personnel of the consulting company.

DBX330-2, DBX440-2, DBX550-2, DBX640-2, DBX730-2, DBX785-2 two-phase disc separators

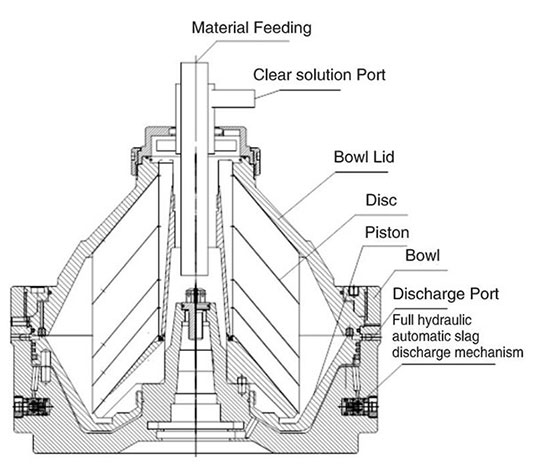

This machine is a disc piston automatic slag discharge drum inner diameter 330mm, 440mm, 550mm, 640mm, 730mm, 785mm liquid-solid two-phase disc separator. The internal structure of X will vary according to different industries and materials used,

This machine is mainly used for the separation of liquid-solid materials with low solid content (generally less than 5%), such as the purification of dairy products; Food: clarification of fruit juice; Beer separation: Separation of fermentation broth from fermented brewing products; Clarification: pharmaceuticals, vaccines, mycelium, glucose, insulin, antibiotics, vitamins; The recovery of solvents, galvanizing solutions, aluminum sulfate solutions, tar water mixtures, polyvinyl chloride, polypropylene, polyethylene, silver (in film processing), catalysts, and magnetite used for dry cleaning in the chemical industry, as well as the removal of solid waste from environmental wastewater.

Basic parameters of two-phase separator

|

Model |

DBX330-2 |

DBX440-2 |

DBX550-2 |

DBX640-2 |

DBX730-2 |

DBX785-2 |

|

Inner diameter of drum mm |

330 |

440 |

550 |

640 |

730 |

785 |

|

Water flow t/h |

5 |

10 |

20 |

30 |

50 |

60 |

|

Working speed rpm |

8500 |

6900 |

6000 |

5300 |

4800 |

4200 |

|

Separation factor (g) |

≥ 12000 |

≥ 10000 |

≥ 9800 |

≥ 9000 |

≥ 8800 |

≥ 7700 |

|

Installed power kW |

7.5 |

15 |

30 |

45 |

55 |

90 |

|

Overall dimension (length◊width◊height) mm |

1150◊850◊180 |

1280◊1250◊1450 |

1720◊1300◊1800 |

1850◊1450◊1880 |

2155◊1750◊1900 |

2555◊2250◊2300 |

|

Net weight kg |

650 |

1100 |

2200 |

2650 |

3900 |

5800 |

The processing capacity varies according to the different materials, welcome the professional and technical personnel of the consulting company.

DBPX330-2, DBPX440-2, DBPX550-2, DBPX640-2, DBPX730-2 two-phase disc separators

This machine is a disc type piston automatic slag discharge+nozzle continuous slag discharge drum with inner diameters of 330mm, 440mm, 550mm, 640mm, 730mm - liquid-solid two-phase disc separator. The internal structure of X will vary according to different industries and materials used.

This machine is a slag discharge+nozzle type separator developed by our company, mainly used for the separation of liquid-solid materials with high solid content (generally 1% -25%), especially suitable for the separation of various solid containing protein, algae, and fermentation liquid cell materials.

Basic parameters of two-phase slag discharge nozzle separator

|

Model |

DBPX330-2 |

DBPX440-2 |

DBPX550-2 |

DBPX640-2 |

DBPX730-2 |

|

Inner diameter of drum mm |

330 |

440 |

550 |

640 |

730 |

|

Water flow t/h |

5 |

10 |

20 |

30 |

50 |

|

Working speed rpm |

8500 |

6900 |

6000 |

5300 |

4800 |

|

Separation factor (g) |

≥ 12000 |

≥ 10000 |

≥ 9800 |

≥ 9000 |

≥ 8800 |

|

Installed power kW |

11 |

18.5 |

37 |

55 |

75 |

|

Overall dimension (length◊width◊height) mm |

1150◊850◊180 |

1280◊1250◊1450 |

1720◊1300◊1800 |

1850◊1450◊1880 |

2155◊1750◊1900 |

|

Net weight kg |

670 |

1130 |

2220 |

2680 |

3900 |

The processing capacity varies according to the different materials, welcome the professional and technical personnel of the consulting company.

Structural characteristics of Huibo dish separator

Product Features

1. The separator absorbs the advantages of the same type of separator at home and abroad, and mainly adopts the international advanced belt drive structure. It has the characteristics of compact and simple structure, stable and reliable operation, convenient maintenance; at the same time, it has the characteristics of high speed, high separation factor, good separator performance, large equivalent settlement area and large production capacity.

2. DB structure adopts full hydraulic automatic clearance slag discharge drum structure, which can realize automatic slag discharge without stopping the machine and without stopping the material, and can adjust the relevant parameters of the electric control box PLC to change the slag discharge volume and slag discharge interval time of each separator, thus ensuring the continuity of industrial production and the fluctuation of material parameters, thus applying the processing requirements of different materials.

3. DBP structure adopts full hydraulic automatic gap slag discharge drum structure nozzle continuous slag discharge structure, which is suitable for the separation of materials with high solid content, especially for the separation of various solid-containing protein, algae and fermentation liquid cell materials.

4. All metal parts in contact with materials are made of stainless steel to meet the requirements of food hygiene and chemical corrosion prevention.

5. The liquid phase outlet of the machine is equipped with a centripetal pump. Therefore, when the machine is used, only an external feed pump is required, and the outlet can be output with a certain pressure to directly go to the next equipment of the process.

Drum structure characteristics

1. The separator drum is made of high-strength stainless steel, and the finite element strength design is carried out on some parts of the separator drum to meet the strength requirements of high speed.

2. The full hydraulic double small valve slag discharge structure is adopted, and the sealing/slag discharge action is reliable; the volume of the slag chamber of the drum is large, which increases the slag discharge adjustment range of the separator and improves the processing capacity.

3. According to the material characteristics, the rotating drum can adopt advanced piston protective sleeve structure, which can effectively protect the piston sealing surface from being damaged during slag discharge and improve the reliability of the separator; the main sealing ring adopts high-strength polymer material instead of the original ordinary nylon Material, prolong the service life of the main sealing ring and save the operating cost of the machine.

4, Separator drum through accurate dynamic balance check, the machine running vibration is small, stable and reliable operation.

Control System Features

1. The control system is equipped with frequency converter, and the separator motor is started by frequency conversion, and the starting time can be adjusted. It has the characteristics of stable starting and small starting current, which meets the requirements of large starting load of the separator. At the same time, the frequency converter has the advantages of regular fault protection, over-current protection, over-voltage protection and so on.

2. The control box adopts PLC automatic control box, which has the powerful function of integrating operation, monitoring/display and adjustment, and realizes the unmanned automatic operation of the normal work of the separator. By adjusting the parameters of the control system, the full discharge/part discharge can be used, and the separation time and the amount of slag discharged each time can be adjusted.

3. The appearance design of the electric control cabinet is beautiful, and the operation buttons are intuitive, convenient and simple.

The main features of the disc separator

1, The separation capacity of the disc separator, the separation factor between 5000-12000, the separation factor is the most important parameter to reflect the separation capacity; compared with other forms of separator (centrifuge), decanter centrifuge separation factor generally the highest can only reach 4000, other types of separation factor is smaller.

2. The production capacity is large. Under the condition of the same occupied area of the workshop, the production capacity of the disc separator is much larger than that of other forms of separators (centrifuges) and related sedimentation filtration equipment. At present, the maximum production capacity of the single disc separator is 100 tons/hour or even higher. The reason why the production capacity of the disc separator is large is that the equivalent settlement area of the large disc separator is quite large, equivalent settlement area of large separator can reach 300 × 107cm2Quite 30000 m2Natural settlement area.

3. Wide application range: during liquid-solid separation, the separator is suitable for almost all industrial materials with solid content of 0.1-20% and particle size of 0.2-100 microns; During liquid-liquid separation, the separator is suitable for almost all industrial materials with a specific gravity difference of more than 0.03 g/ml between the two liquid phases.

4, Strong mobility, according to the need for automatic or manual operation, can also achieve remote automatic operation.

5, Easy maintenance. Compared with other types of separators, the whole machine of the disc separator is lighter in weight, the corresponding collar parts are also light in weight, and the mechanism is simple, so its maintenance, assembly and disassembly are convenient.

The main purpose of the disc separator

The overall is mainly applicable

1, the general solid content between 0.5-5%, solid particle diameter of 0.5-100 microns of liquid-solid or liquid-liquid-solid separation.

2. Three-phase separation, such as oil: vegetable oil, animal oil, fish oil, crude oil, various raw materials oil, biodiesel, lubricating oil separation.

3. Two-phase clarification: purification of dairy products; food: clarification of fruit juice; beer separation: separation of fermentation liquid in fermented brewing products; clarification: pharmacy, vaccine, mycelium, glucose, insulin, antibiotics and vitamins; extraction of molasses mercerized lye No.2: chemical industry, dry cleaning agent, zinc plating solution, aluminum sulfate solution, tar water mixture, polyvinyl chloride, polypropylene, polyethylene, silver (film processing) and catalyst and magnet ore recovery.

4. The continuous nozzle separator is used for solid concentration and solid classification with a solid content of 5-25% and a solid particle diameter of 0.5-100 microns. It is a two-phase separation when used for solids concentration and a three-phase separation when used for particle classification.

5. The slag discharge nozzle type separation function developed by our company is especially suitable for the separation of various solid-containing protein, algae and cell materials.

At present, disc separators are widely used and are used in almost all fields of liquid-solid and liquid-solid separation, such as: purification of fuel oil and lubricating oil; clarification and purification of fresh milk, degreasing of dairy products; purification and clarification of palm oil, degumming, desoaping, dehydration and dewaxing of animal and vegetable oil refining; clarification of beer, fruit juice, beverage, extraction of vegetable protein, wastewater treatment, etc.; clarification of bioengineering fermentation liquor; concentration and classification of starch slurry; Purification or clarification in the extraction process of antibiotics and biochemical drugs, clarification of traditional Chinese medicine, etc. Purification or clarification of chemical raw materials; Extraction and purification of lanolin; Purification and concentration of latex; In addition, laboratories, petroleum, coking, kaolin, pulp recovery, electrolyte treatment, wastewater treatment, environmental protection, etc. are all used.