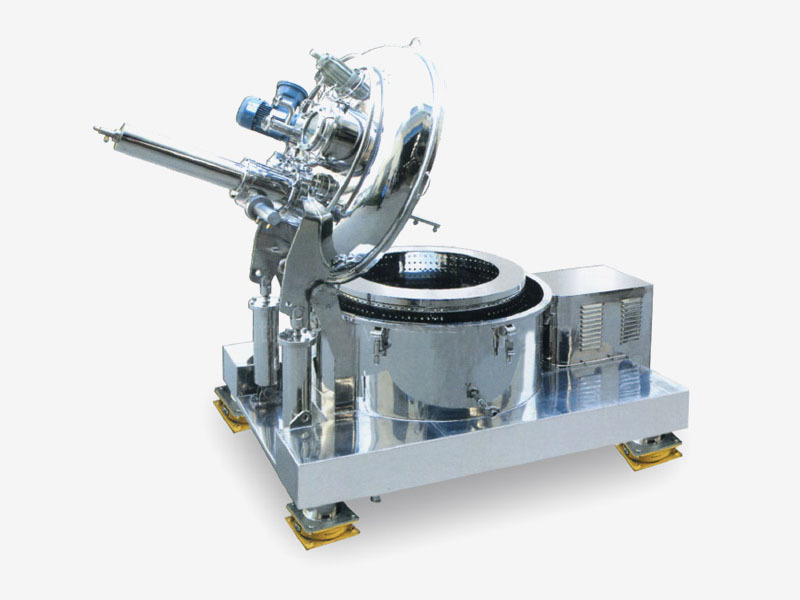

Closed Explosion-Proof Horizontal Scraper Discharge Centrifuge

Contact Us

Classification

Keywords

Centrifuge

quality Centrifuge

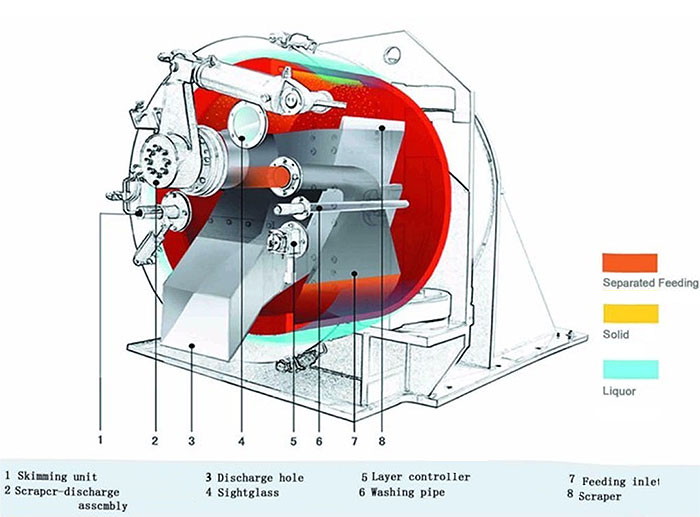

Product Introduction

GK type horizontal scraper discharge centrifuge is to open the feed valve after starting to feed speed, the separated suspension enters the drum through the cloth hopper and is evenly distributed on the filter medium on the inner wall of the drum. Under the action of centrifugal force, the liquid phase is thrown out of the drum through the filter medium and the small holes on the drum, and the solid phase is trapped on the filter medium to form a filter cake. When the filter cake layer reaches a certain thickness, close the feed valve to wash the solid phase, and then spin dry. Finally, the filter cake layer is removed by rotating scraper, and the material is discharged out of the machine in two ways: chute or spiral conveying.

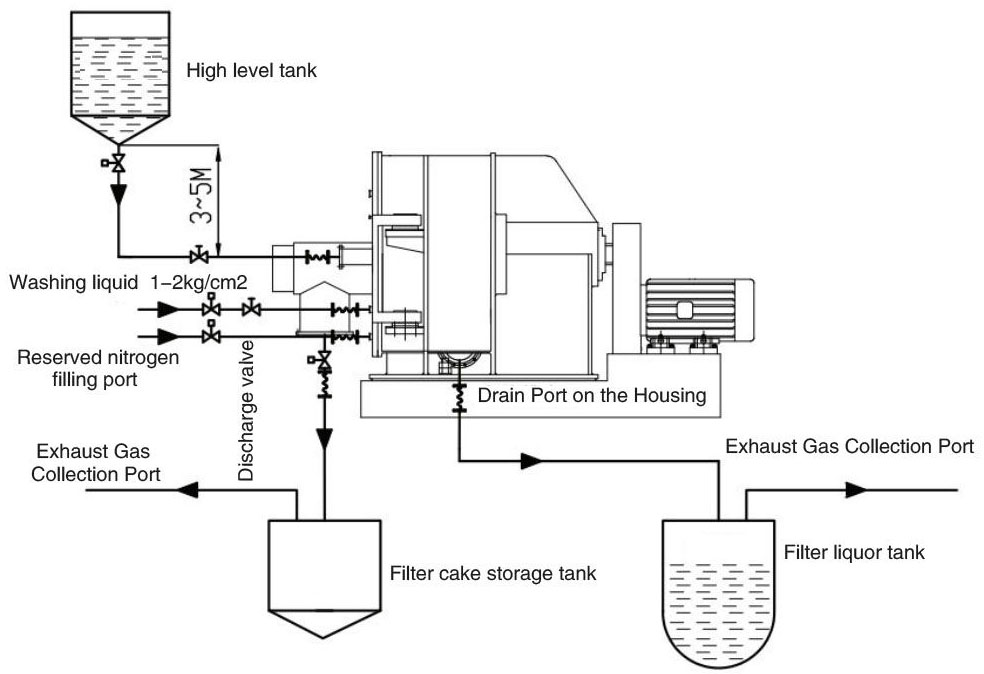

Process Flow Diagram of GK Horizontal Scraper Discharging Centrifuge

Structure, performance characteristics

(1) Automatic operation, manual labor intensity is small;

(2) The implementation of the components of the hydraulic system for automatic control, stable and reliable operation;

(3) Electrical PLC control, accurate action, easy to adjust;

(4) The use of frequency converter or hydraulic coupling transmission, start and stop smoothly;

Scope of application

Can be widely used in food, chemical, pharmaceutical, light industry and other industries.

Typical Application Materials

Starch, potassium chloride, salt, heavy alkali, caustic soda, diglycin, sodium cyanide, calcium hydrogen phosphate, ammonium chloride, etc.

Main specifications and technical parameters

| Item/Model | GK800-NB | GK1250-NB | Gk1400-na | GK1600-NA/ND |

| Drum diameter (mm) | 800 | 1250 | 1400 | 1600 |

| Drum length (mm) | 450 | 600 | 800 | 800 |

| Drum speed (r/min) | 1550 | 1200 | 1150 | 950 |

| Loading Limit Weight (kg) | 130 | 400 | 700 | 850 |

| Loading volume (L) | 100 | 310 | 550 | 680 |

| Separation factor | 1070 | 1006 | 1036 | 800 |

| Main motor power (kW) | 37/30 | 55 | 90 | 110 |

| Overall dimension (mm) | 2460×1670×1300 | 3100×2070×1775 | 4330×2325×1900 |

3885×2725×2220/ 4720×2725×2220 |

| Machine weight (kg) | 3350 | 7420 | 10700 | 12400/12800 |

A centrifuge is a high-precision laboratory and industrial device designed to separate components of a mixture based on their density through rapid spinning. By generating strong centrifugal force, it pushes heavier particles outward while lighter components remain closer to the center, enabling effective separation of liquids, solids, and suspensions. Centrifuges are widely used in clinical laboratories for blood component separation, in chemical and pharmaceutical industries for isolating compounds, in wastewater treatment for sludge dewatering, and in food processing for clarifying liquids such as milk, juice, and oils.

Modern centrifuges feature programmable speed control, temperature regulation, and automated timers to ensure precise and reproducible results. They are available in various types, including benchtop models for small-scale laboratory use, high-speed refrigerated units for temperature-sensitive samples, and large industrial centrifuges for continuous processing of bulk materials. Safety features such as imbalance detection, lid locking mechanisms, and emergency stop functions protect operators and prevent equipment damage.

The efficiency of a centrifuge depends on factors such as rotor design, rotational speed, and sample volume. Fixed-angle rotors hold tubes at a constant angle for rapid pelleting of solids, while swinging-bucket rotors allow more even separation for layered components. Ultracentrifuges can achieve extremely high rotational speeds, generating forces thousands of times stronger than gravity, which is essential for separating microscopic particles, proteins, or nucleic acids in molecular biology research.

Centrifuges contribute significantly to laboratory workflow efficiency, product quality, and research accuracy. Proper maintenance, including regular cleaning, calibration, and rotor inspection, ensures consistent performance and extends the equipment’s lifespan. With their versatility, reliability, and precision, centrifuges remain indispensable tools in science, industry, and healthcare.