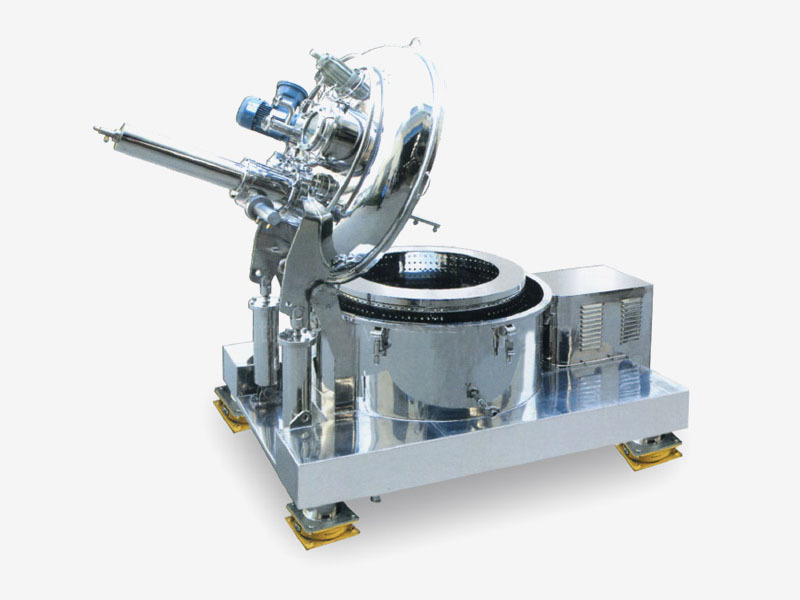

Plate Type Hanging Bag Unloading Centrifuge

Contact Us

Classification

Keywords

Centrifuge

best Centrifuge

Main features

- The welding position of the structural part is arc transition, all stainless steel surfaces are polished to eliminate sanitary dead ends, and the material contact part is made of stainless steel.

- The material adopts filter bag with special structure and unloads with lifting device. The unloading process has low labor intensity, does not cause damage to the grain of the material, and can maintain the pure state of the material.

- The machine cover can be opened to effectively clean the space between the centrifuge shell and the rotating drum. The opening of the cover can be configured with manual flip cover or hydraulic and pneumatic automatic flip cover.

- Flat plate structure, lower the center of gravity of the machine, the base plate can be used as an operating platform.

- Equipped with liquid damping shock absorber, the vibration reduction efficiency is high.

- The machine cover is provided with feeding pipe, washing pipe, observation mirror and illumination hole. Optional online cleaning system, the inner wall of the centrifuge shell, the inner and outer surfaces of the drum, the surface of the sump and other invisible parts of the centrifuge cleaning, in line with GMP specifications.

- The grains are not easy to break, and can be used for the separation of solid-phase granular suspensions, and can also be used for the separation of fibrous materials, with a wide range of applications.

- The inverter starts, starts smoothly, and the separation factor is adjustable.

- Closed structure, the seal is made of silicone rubber or fluorine rubber, etc., and the optional nitrogen protection system can achieve the requirements of closed explosion-proof, suitable for the application of toxic and flammable and explosive occasions.

- Direct explosion-proof motor can be used to eliminate the friction dust generated by belt drive; at the same time, because the motor is installed at the bottom of the machine, the centrifuge covers a smaller area.

Working principle

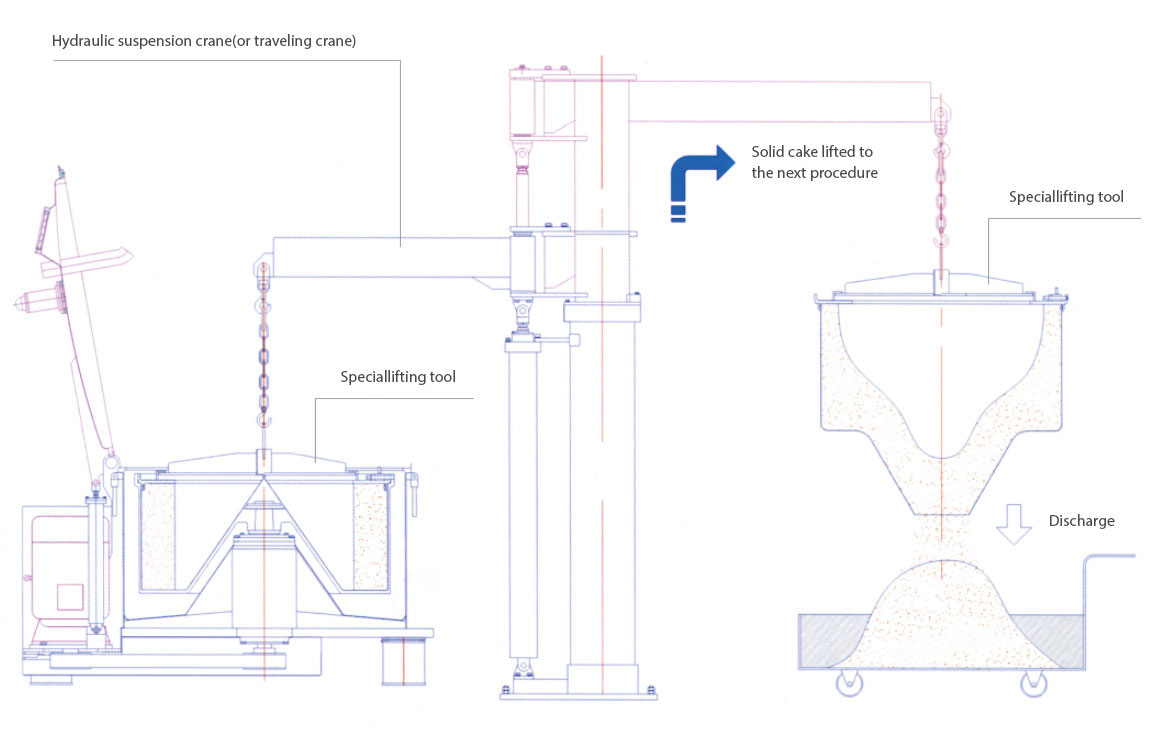

The material to be separated enters the high-speed rotating centrifuge drum through the feed pipe. Under the action of the centrifugal force field, the material is filtered through the filter cloth (filter screen), the liquid phase is discharged through the liquid outlet pipe, and the solid phase is trapped in the drum. When the filter cake in the drum reaches the loading amount specified by the machine, stop the feeding, wash the filter cake, and filter out the washing liquid at the same time. Stop the machine after the filter cake deliquification meets the requirements. The special lifting device will lift the filter bag together with the filter cake to the designated discharge place, open the discharge port, discharge the filter cake, and then reset the filter bag to enter the standby state.

Schematic Diagram of Discharge

Technical parameters

| Project | PSD800 | PSD1000 | PSD1250 | PSD1500 | PSD1800 |

| Drum diameter (mm) | 800 | 1000 | 1250 | 1500 | 1800 |

| Drum volume (L) | 120 | 200 | 400 | 600 | 910 |

| Maximum loading limit (kg) | 150 | 250 | 500 | 800 | 1100 |

| Drum speed (r/min) | 1200/1500 | 1100/1200 | 1000/1200 | 850 | 780 |

| Separation factor | 645/1006 | 680/806 | 700/1008 | 607 | 612 |

| Motor power (kw) | 7.5 | 11 | 18.5/22 | 30 | 37 |

|

Overall dimension (LxWxH) (mm) |

1750x1200x1300 | 2000x1400x1500 | 2550x1800x1750 | 2600x2300x1800 | 3300x2600x2100 |

| Machine weight (kg) | 1500 | 2500 | 4000 | 6000 | 10000 |

A centrifuge is a specialized device designed to separate components of a mixture based on their density using high-speed rotational force. By generating centrifugal force, it efficiently separates liquids, solids, and semi-solids, making it an essential tool in laboratories, industrial processes, medical diagnostics, chemical processing, and wastewater treatment. Centrifuges are widely used in biology, chemistry, pharmaceuticals, food processing, and environmental industries due to their accuracy, efficiency, and reliability in separating complex mixtures.

Working Principle

The centrifuge operates on the principle of centrifugal force, which acts outward on particles within a spinning rotor. Denser particles move outward to the perimeter, while lighter particles remain closer to the center. By adjusting speed, rotor type, and duration, users can precisely control the separation of components such as blood plasma, suspended solids, chemical precipitates, or emulsions. The process is rapid, reproducible, and highly efficient compared to traditional gravitational separation methods.

Types of Centrifuges

Centrifuges come in various designs to suit different applications:

-

Benchtop Laboratory Centrifuges: Compact and versatile, ideal for small sample volumes in research and diagnostic labs.

-

High-Speed and Ultracentrifuges: Capable of extremely high rotational speeds for separating fine particles, macromolecules, and subcellular components.

-

Industrial Centrifuges: Used for large-scale separation of liquids and solids in chemical, pharmaceutical, and food industries.

-

Refrigerated Centrifuges: Maintain temperature-sensitive samples during separation, essential for biological and biochemical applications.

-

Continuous-Flow Centrifuges: Designed for ongoing processing of large volumes in wastewater treatment, milk processing, and chemical manufacturing.

Key Features

Modern centrifuges offer advanced features for precision, safety, and convenience:

-

Adjustable Speed and Time: Customize separation parameters according to sample type.

-

Multiple Rotor Options: Accommodate tubes, bottles, or containers of varying sizes.

-

Temperature Control: Preserve sensitive samples with refrigeration or heating options.

-

Automated Programs: Pre-set separation protocols for consistent and reproducible results.

-

Safety Mechanisms: Automatic lid locking, imbalance detection, and emergency shut-off to prevent accidents.

Applications

-

Laboratory Research: Separating blood components, proteins, DNA, and cell organelles.

-

Medical and Clinical Diagnostics: Blood testing, plasma separation, urine analysis, and pathogen isolation.

-

Pharmaceutical Industry: Purification of drugs, vaccines, and chemical compounds.

-

Food and Beverage: Clarification of juices, milk, oils, and fermentation products.

-

Environmental Engineering: Treating wastewater, separating sludge, and recycling processes.

-

Chemical Industry: Solid-liquid separation, chemical precipitation, and catalyst recovery.

Advantages

-

Rapid and efficient separation of complex mixtures.

-

High reproducibility and accuracy for research and industrial processes.

-

Versatility across different sample types and volumes.

-

Temperature control for handling sensitive samples.

-

Safe and easy to operate with modern automation features.

Maintenance and Safety

Proper maintenance ensures the longevity and reliable performance of centrifuges:

-

Regular cleaning of rotors and sample holders.

-

Inspection for wear, corrosion, or imbalance.

-

Adherence to manufacturer guidelines for load limits and operating conditions.

-

Ensuring proper balance and secure sealing of tubes or containers before operation.

Centrifuges are indispensable tools for separating, purifying, and concentrating materials across scientific, medical, and industrial fields. With precise control, efficiency, and robust safety features, centrifuges enable faster, more reliable results, supporting research, production, and quality control in diverse applications.