Three-Phase Horizontal Spiral Discharge Sedimentation Centrifuge

Contact Us

Classification

Keywords

Centrifuge

Sedimentation Centrifuge

Sedimentation Centrifuge source

Three-Phase Horizontal Spiral Discharge Sedimentation Centrifuge

Product Introduction

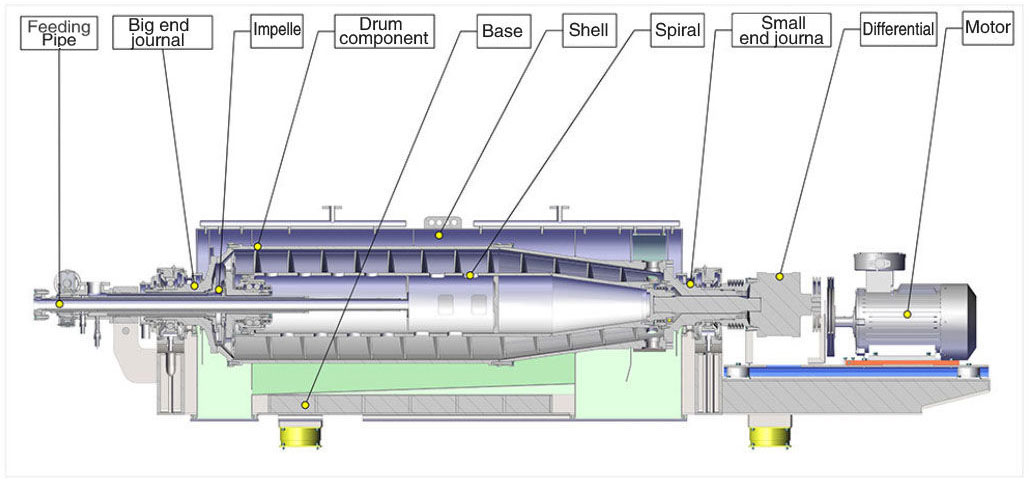

LWS series horizontal spiral discharge sedimentation three-phase centrifuge is mainly composed of spiral/drum, differential, dual motors (main and auxiliary motors), dual frequency converters, integrated machine base, fully closed casing, feed pipe assembly, adjustable centripetal pump, casing and automatic control system. It can separate liquid-liquid-solid or liquid-solid-liquid three-phase for various suspensions with large physical property differences.

The suspension to be separated is continuously transported into the machine through the feed pipe. After being accelerated by the silo of the screw conveyor, it enters the high-speed rotating drum. Under the action of the centrifugal force field, the suspension forms an annular liquid flow in the drum. The solid particles quickly settle on the inner wall of the drum under the action of the centrifugal force. The differential speed between the drum and the screw is generated by the screw to push the sediment to the drying area at the cone end of the drum, after the two-way action of spiral thrust and centrifugal force, the sediment is further dewatered and discharged from the small end of the drum.

The annular liquid flow forms obvious stratification effect of two liquid phases through the difference of specific gravity. The heavy liquid phase is near the drum cylinder, and the light liquid phase is far away from the drum cylinder. The different separation effects of sediment and liquid phase are obtained by adjusting the overflow plate at the big end of the drum, and the different separation effects of two liquid phases can be achieved by adjusting the interface between the two liquid phases without stopping the machine.

The separated light liquid is discharged through the overflow port, while the separated heavy liquid is discharged through the pressure of the centripetal pump at the big end of the drum. The sediment and clear liquid are collected into the respective collection bins in the casing, and finally discharged out of the machine under the action of gravity.

Working Schematic Diagram

Product Features

In addition to the characteristics of ordinary decanter centrifuge, it also has the following characteristics:

1. The separation area of the two liquids can be adjusted online through the adjustable centripetal impeller, the heavy phase hydraulic pressure is discharged, and the light phase liquid is discharged by gravity. The separation degree of heavy and light liquids can be quickly and freely adjusted to obtain higher liquid purity.

2, Through the adjustable impeller, eliminating the traditional separation pump, saving costs and adjusting the scale is easy to read, easy to operate.

3. Directly enter the liquid outlet pipe from the inner cavity of the drum through the centripetal pump, and discharge the two liquid phases through independent channels, thus effectively avoiding cross contamination between heavy liquid and light liquid and not contacting with outside air. It is suitable for occasions where the liquid phase is volatile, flammable and explosive, foaming, a small amount of suspended solids, toxic and secondary pollution of the liquid phase.

4. It can adapt to the fluctuation of feed volume and three-phase feed concentration ratio at any time.

Main technical parameters

| Item/Model | LWS350 | LWS450 | LWS550 | LWS650 | LWS750 | LWS850 |

Drum diamete r(mm) (Inner diameter of column section drum) | 350 | 450 | 550 | 650 | 750 | 850 |

Drum aspect ratio(L/D) | 3~4 | 3~4 | 3~4 | 3~4 | 2~4 | 2~4 |

Drum speed (r/min) | 4000 | 3500 | 3300 | 3200 | 2800 | 2500 |

Separation factor | 3136 | 3087 | 3354 | 3727 | 3293 | 2975 |

Main motor power(kW) | 15~30 | 30~45 | 37~55 | 55~90 | 75~110 | 90~132 |

Auxiliary motor power(kW) | 7.5~11 | 7.5~18.5 | 15~22 | 22~45 | 30~55 | 45~75 |

Overall dimension (LxWxH)(mm) | 3540*850*1296 | 4356*1190*1383 | 5294*1408*1522 | 6351*1550*1840 | 7013*1810*2200 | 7000*2850*1677 |

Whole machine weight(kg) | 2600 | 5200 | 6500 | 9500 | 13000 | 19500 |

Three-phase horizontal spiral discharge sedimentation centrifuge ensures continuous separation of solids, oil and water efficiently.