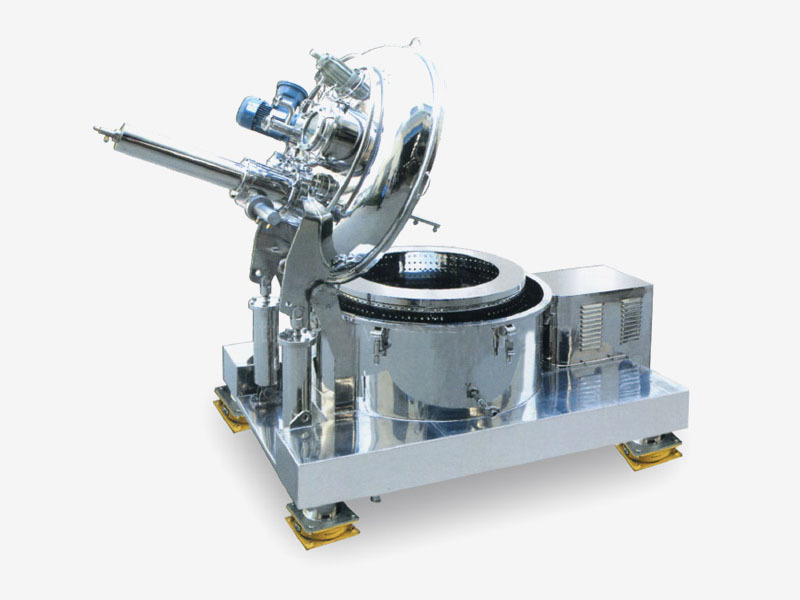

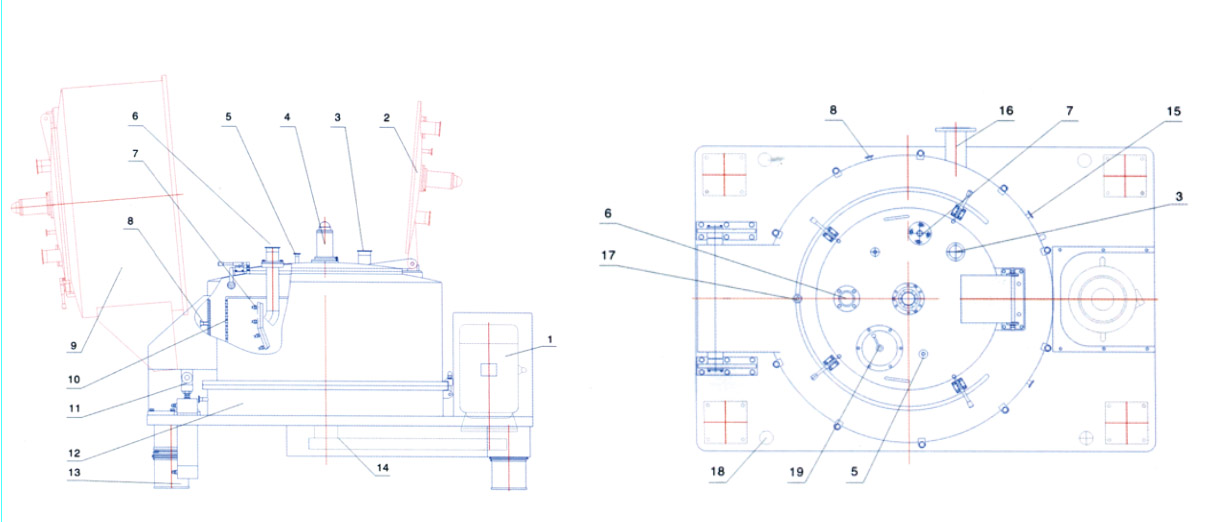

Plate Type Manual Discharge Centrifuge

Contact Us

Classification

Keywords

Centrifuge

Plate Type Manual Discharge Centrifuge

Main features

- Full flip cover structure, structural transition smooth, surface polished, effectively eliminate the health dead angle, external structural parts, fasteners and drum made of stainless steel, can be on the centrifuge shell, drum, liquid tank for thorough cleaning.

- The machine base is a flat plate structure, the center of gravity of the machine is low, the space is small, and the operation is convenient.

- Equipped with liquid damping shock absorber, good damping effect, simplify daily maintenance.

- The flip cover is provided with a feeding pipe, a washing pipe, an observation mirror and a lighting hole. Configuration of online cleaning system (optional), the inner wall of the centrifuge shell, the inner and outer surface of the drum, the surface of the liquid collection tank and other internal centrifuge online cleaning, to ensure the cleanliness requirements, in line with GMP specifications.

- It has strong versatility and the grains are not easy to break. It can be used for the separation of solid-phase granular suspensions and the separation of fibrous materials. It has a wide range of applications.

- The use of frequency converter to start, start smoothly, the separation factor is adjustable; configure nitrogen protection system (optional), can achieve the requirements of closed structure explosion-proof, suitable for toxic and flammable and explosive applications.

- Can be configured manually, hydraulic and other flip form.

Working principle

The material to be separated enters the high-speed rotating centrifuge drum through the feed pipe. Under the action of the centrifugal force field, the material is filtered through the filter cloth (filter screen), the liquid phase is discharged through the liquid outlet pipe, and the solid phase is trapped in the drum. When the filter cake in the drum reaches the loading quantity specified by the machine, the feed is stopped, the filter cake is washed, and the washing liquid is filtered out at the same time. After the filter cake deliquification meets the requirements, stop the machine and discharge the filter cake manually. Enter the standby state.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PQSB Technical Parameters

| Project | PQSB600 | PQSB800 | PQSB1000 | PQSB1250 |

| Drum diameter (mm) | 600 | 800 | 1000 | 1250 |

| Drum volume (L) | 45 | 100 | 150 | 310 |

| Maximum loading limit (kg) | 60 | 125 | 200 | 380 |

| Drum speed (r/min) | 1500 | 1200 | 1100 | 1000 |

| Separation factor | 755 | 645 | 680 | 700 |

| Motor power (kw) | 3 | 7.5 | 11 | 18.5 |

| Overall dimension (LxWxH) (mm) | 1900x1300x1300 | 2200x1450x1350 | 2450x1500x1400 | 2450x1700x1650 |

| Machine weight (kg) | 1100 | 1500 | 2200 | 3200 |

PQFB Technical Parameters

| Project | PQFB600 | PQFB800 | PQFB1000 | PQFB1250 |

| Drum diameter (mm) | 600 | 800 | 1000 | 1250 |

| Drum volume (L) | 45 | 100 | 150 | 210 |

| Maximum loading limit (kg) | 60 | 125 | 200 | 260 |

| Drum speed (r/min) | 1500 | 1200 | 1100 | 1000 |

| Separation factor | 755 | 645 | 680 | 700 |

| Motor power (kw) | 3 | 7.5 | 11 | 18.5 |

| Overall dimension (LxWxH) (mm) | 1900x1300x1300 | 2400x1300x1650 | 2450x1500x1650 | 3000x1650x1550 |

| Machine weight (kg) | 1100 | 2000 | 2600 | 3500 |

A Plate Type Manual Discharge Centrifuge is a specialized separation device designed to efficiently separate solids from liquids in various industrial and laboratory processes. This type of centrifuge utilizes a series of stacked conical plates inside a rotor to increase the settling area, enhancing separation efficiency and reducing retention time. The manual discharge design allows operators to easily remove accumulated solids after the separation process, ensuring continuous operation and simplified maintenance.

Working Principle

The centrifuge operates on centrifugal force generated by high-speed rotation. A mixture of liquid and suspended solids is fed into the rotor, where centrifugal acceleration forces the denser solid particles outward toward the rotor wall. The conical plate stack provides multiple settling surfaces, allowing solids to settle more efficiently and liquids to flow toward the central outlet. Once the separation cycle is complete, the operator manually discharges the accumulated solids through a discharge port or rotor opening. This manual discharge design is particularly suitable for processes with intermittent solid removal requirements or when handling sticky or challenging materials.

Construction and Design

The plate type manual discharge centrifuge typically consists of the following components:

-

Rotor and Plate Stack: Precision-engineered rotor with conical plates for enhanced separation efficiency.

-

Bowl and Casing: Durable construction to withstand high rotational speeds and pressures.

-

Feed System: Designed to introduce liquid-solid mixtures evenly into the rotor.

-

Discharge Mechanism: Manual discharge port or top cover allowing operator-controlled solids removal.

-

Drive System: Motorized drive with variable speed control for process flexibility.

-

Safety Features: Protective covers, imbalance detection, and emergency stop mechanisms.

The use of corrosion-resistant materials such as stainless steel ensures long-term durability and reliability, even when handling corrosive or abrasive slurries.

Key Features

-

High Separation Efficiency: Stacked conical plates maximize settling area, improving liquid clarification.

-

Manual Discharge: Simple, cost-effective method for solids removal without complex automated systems.

-

Flexible Operation: Adjustable speed and feed rate allow precise control of separation.

-

Durable Construction: Stainless steel and wear-resistant components extend service life.

-

Versatility: Handles a wide range of slurry concentrations and particle sizes.

-

Low Maintenance: Easy access to rotor and plates simplifies cleaning and inspection.

Applications

Plate type manual discharge centrifuges are widely used across industries, including:

-

Chemical Industry: Separation of catalysts, chemical precipitates, and emulsions.

-

Pharmaceuticals: Clarification of suspensions, recovery of active ingredients, and preparation of chemical intermediates.

-

Food and Beverage: Juice clarification, oil separation, and dairy processing.

-

Environmental Engineering: Sludge dewatering, wastewater treatment, and industrial effluent management.

-

Mining and Mineral Processing: Separation of fine solids from liquids in mineral slurries and tailings management.

This type of centrifuge is particularly suited for small to medium-scale production where solids removal is required at regular intervals, offering flexibility and reliable performance without the need for complex automation.

Advantages

-

Efficient solid-liquid separation with enhanced clarity of the liquid phase.

-

Manual discharge allows operator control, suitable for varying process requirements.

-

Robust design and corrosion-resistant materials ensure long service life.

-

Low operational and maintenance costs compared to fully automated centrifuges.

-

Flexible operation suitable for a wide range of industries and applications.

Maintenance and Operational Considerations

Regular maintenance ensures optimal performance and safety:

-

Inspect rotor, plates, and discharge ports for wear or damage.

-

Clean the bowl, plate stack, and feed system after each operation to prevent residue buildup.

-

Check motor and drive system for proper function and lubrication.

-

Ensure balanced loading to prevent vibration and mechanical stress.

-

Follow manufacturer guidelines for speed limits and operational procedures.

Conclusion

The Plate Type Manual Discharge Centrifuge provides a reliable and efficient solution for solid-liquid separation in laboratories and industrial processes. Its conical plate design enhances separation efficiency, while the manual discharge feature allows easy removal of solids, making it suitable for processes with intermittent or variable solids handling requirements. With robust construction, flexible operation, and low maintenance demands, this centrifuge is an ideal choice for industries ranging from chemicals and pharmaceuticals to food processing and environmental management.