Horizontal Three-Stage Piston Pusher Centrifuge

Contact Us

Classification

Keywords

Centrifuge

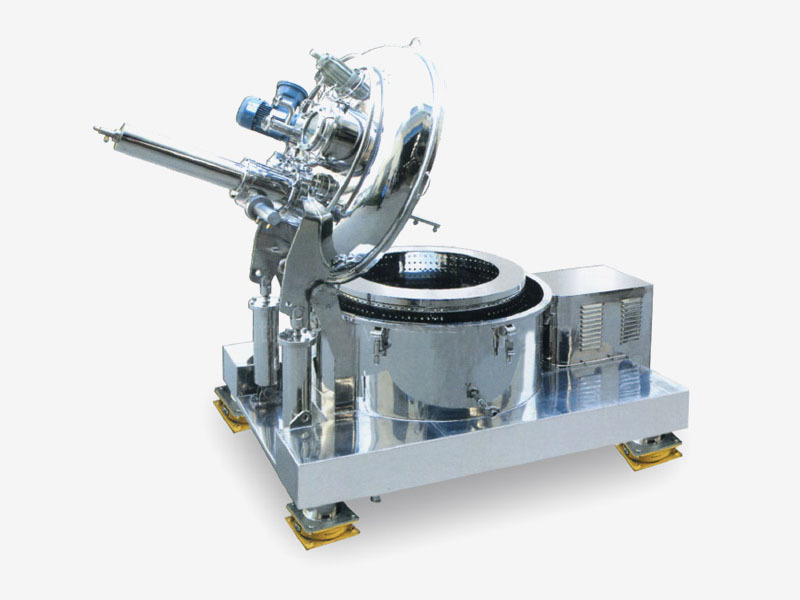

Horizontal Three-Stage Piston Pusher Centrifuge

Working principle

HS series three-stage piston pusher centrifuge is a two-stage pusher centrifuge based on the addition of a three-stage drum, the material from the two-stage drum to the three-stage drum after further dehydration. After adding a filtration zone, the filtration zones at all levels can be shortened while keeping the total length of the filtration zone unchanged, making it easier to handle materials that are prone to agglomeration and accumulation.

Model and main technical parameters

Item/Model | HS420-NB | HS550-NB | HS650-NB | HS800-NB | HS1000-NB |

Inner diameter of drum (mm) | 300/357/420 | 390/460/500 | 510/580/650 | 650/720/800 | 836/916/1000 |

Length of filtration area (mm) | 120/120/120 | 120/120/120 | 140/160/140 | 180/240/180 | 200/240/200 |

Drum speed (r/min) | 1400-2300 | 1200-2000 | 1000-1800 | 800-1600 | 850-1200 |

Separation factor | 426-1243 | 400-1120 | 350-1140 | 290-1150 | 405-1612 |

Pusher stroke (mm) | 40 | 50 | 50 | 50 | 65-75 |

Pusher times (min-1) | 30-80 | 50-75 | 30-80 | 30-80 | 60-80 |

Main motor power (kW) | 15 | 37-55 | 45-75 | 55-90 | 90-132 |

Motor power of oil pump (kW) | 7.5 | 22 | 30 | 45 | 55-75 |

Processing capacity (t/h) | 2-2.5 | 12-18 | ≥ 30 | ≥ 50 | ≥ 70 |

Net weight of machine (kg) | 2500 | 3357 | 3950 | 6500 | 14000 |

Overall dimension (mm) | 2530*1290*1155 | 3710*1380*1750 | 3115*1500*1360 | 3650*1880*1610 | 4050*2150*1990 |

Horizontal three-stage piston pusher centrifuge designed for efficient solid-liquid separation in industrial processes.