Horizontal Spiral Discharge Sedimentation Filtration Integrated Centrifuge

Contact Us

Classification

Keywords

Centrifuge

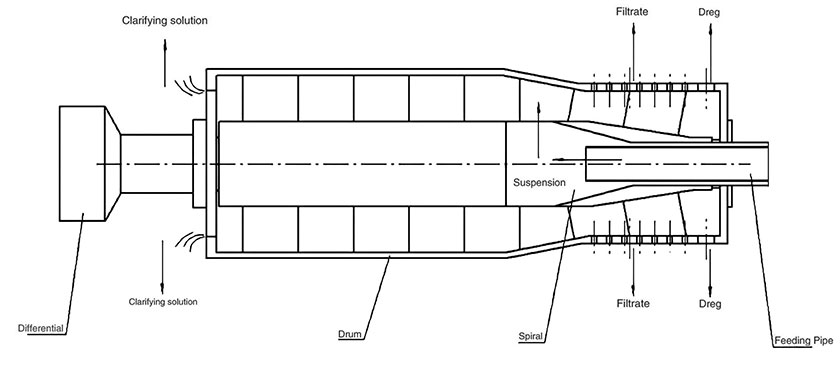

Product Principle

After the material enters the feed pipe, it is accelerated by the distribution bin of the screw conveyor and enters the high-speed rotating drum. Under the action of centrifugal force field, the suspension forms an annular liquid flow in the drum, and the solid particles quickly settle on the inner wall of the drum under the action of centrifugal force.

The separated clarified liquid is discharged through the overflow port, and the solid particles are pushed to the drum filter section after being pre-concentrated by the cone section drum under the action of the spiral. Through centrifugal filtration, the sediment is further dehydrated and discharged from the slag discharge port at the small end of the drum, and a small amount of filtrate is produced during the dehydration process. The dewatering process can wash the filter residue to obtain a purer solid phase.

The whole separation process is carried out continuously. The clarified liquid, filter cake and filtrate are respectively collected into the respective collection bins in the casing, and finally the discharged materials are collected by the casing and discharged out of the machine under the action of gravity.

Work Flow Diagram

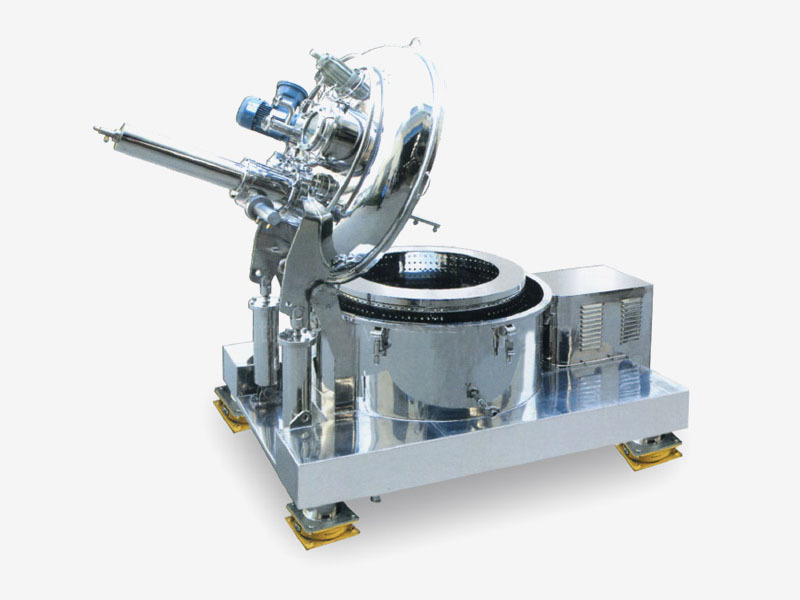

Product Structure

LWC type horizontal spiral discharge sedimentation filtration centrifuge, is based on the horizontal spiral discharge centrifuge structure, increase the filter section drum and design of concentration, sedimentation and dehydration integration equipment. It is mainly composed of rotating body (drum combination, screw, big end journal combination, small end journal combination), differential, feed pipe, machine base, casing, backwashing device, power system and lubrication system.

Product Advantages

- High speed, clear liquid clarification ability, clear liquid solid content is very low.

- A clearer recovery of the liquid phase and a drier dehydration of the solid phase can be obtained.

- Suitable for a wide range of concentration (2%-50%), larger particles (0.05-5mm) slurry concentration, dehydration integration operation.

- Integral strip screen, screen long service life; using special removal tools, easy to replace.

- The operation process is fully automatic and continuous, without manual intervention.

Product Application

Para-xylene, bisphenol A, polyvinyl alcohol, polyethylene, polypropylene, polystyrene, polyvinyl chloride, terephthalic acid, dimethyl ester, mirabilite and mirabilite production residues, potassium salt production residues, waste water salt.

Product Parameters

| Item/Model | LWC550 | LWC650 | LWC750 | LWC850 | LWC950 | LWC1050 |

| Diameter (mm) | 550 | 650 | 750 | 850 | 950 | 1050 |

| Aspect ratio | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3 |

|

Straight filter section(mm) |

360 | 470 | 540 | 640 | 720 | 900 |

|

Filtration length (mm) |

400 | 500 | 600 | 700 | 750 | 900 |

|

Maximum speed (r/min) |

3000 | 2700 | 2500 | 2200 | 2000 | 1700 |

|

Maximum separation factor |

2772 | 2654 | 2625 | 2304 | 2128 | 1699 |

|

Main motor power(kW) |

55-75 | 90-160 | 160-250 | 200-355 | 250-450 | 400-710 |

|

Auxiliary motor power (kW) |

11-30 | 14-45 | 30-65 | 55-90 | 75-110 | 90-132 |

| Weight (kg) | 7750 | 11000 | 13500 | 17500 | 23500 | 31000 |

|

Overall dimension (LxWxH)(mm) |

4115*1905*1410 | 4500*1900*1500 | 5050*2100*1610 | 5700*3230*1750 | 6350*3445*1915 | 7550*3900*2100 |