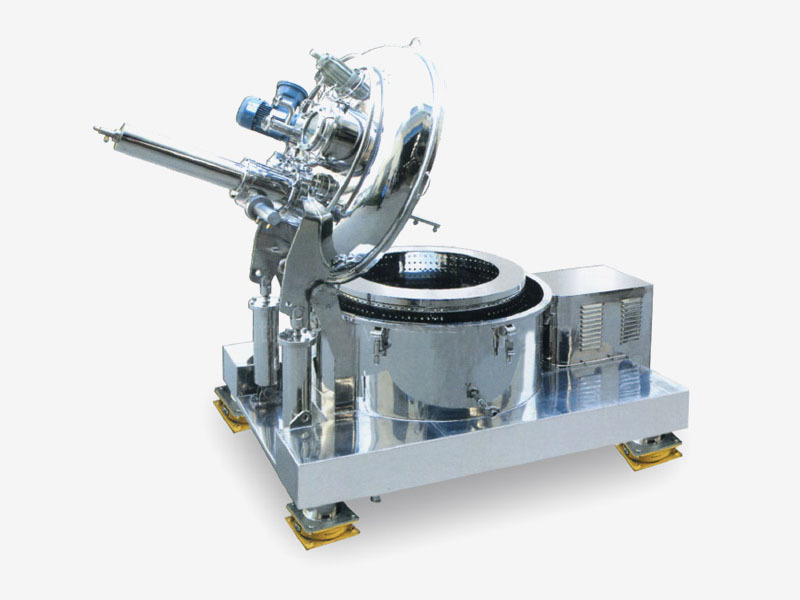

Top-Suspended Scraper Discharge Centrifuge

Contact Us

Classification

Keywords

Top-Suspended Scraper Discharge Centrifuge

Working principle

Top-Suspended Scraper Discharge Centrifuge is mainly composed of drum, drive system, shaft seat, upper casing, shell, spindle, scraper group, etc. The structure is that the transmission system is placed on the top, the vertical motor directly drives the spindle through the coupling, and the drum is fixed at the lower end of the spindle.

The working principle of the Top-suspended centrifuge: the motor drives the drum to rotate. When the feeding speed is reached, the suspension material to be separated enters the high-speed rotating drum through the feeding pipe. After the feeding reaches the predetermined volume, the feeding is stopped. The drum rises to the high-speed separation speed. Under the action of the centrifuge, the material is filtered through the filter cloth (filter screen), and the liquid phase passes through the filter layer through the drum hole to the cavity and is discharged through the liquid discharge pipe, the solid phase is trapped in the drum to form round filter cake, and then the filter cake can be washed. After the separation requirements are met, the rotation speed drops to the discharge rotation speed state, the lower drum casing moves downward along the axis direction, and the scraper device acts to scrape the filter cake from the inner wall of the drum to discharge the lower discharge port of the centrifuge.

Main features

1. The centrifuge is driven by motor frequency conversion and fully automatic cycle operation. In the periodic automatic cycle operation, the frequency conversion stepless speed regulation realizes the optimal operation to meet the requirements of vulgar feeding, high-speed separation and low-speed unloading on the speed to the maximum extent.

2. The centrifuge adopts feedback braking, which has a significant energy-saving effect.

3. The electrical control adopts programmable logic controller (PLC), which can set the time of each process, and the real-time working status of each process is displayed on the operation screen.

4. According to the process requirements, a closed structure type can be adopted and an inerting automatic control system can be configured to achieve inerting protection inside the machine.

5. The overall structure of the centrifuge is compact and the operation is stable.

6, large production capacity, high degree of automation, high speed, good separation effect, low noise, low labor intensity.

7. Optional remote self-service fault diagnosis system.

8. Level detection: mechanical level detection, intelligent camera level detection system.

Application areas

The Top-suspended centrifuge is widely used, from fine particles of starch to medium coarse particles of sugar, especially suitable for the separation of fine sticky materials, widely used in chemical, light industry, pharmaceutical and other industries, such as edible sugar, glucose, methyl sugar paste, calcium hydrogen phosphate, monosodium glutamate, boric acid, borax, calcium carbonate, starch, potassium chlorate, gypsum and other materials.

Main product specifications and parameters

The solid grains are fine and the texture is compact. The drum adopts a cylindrical simplified structure, and the material can be scraped off the drum wall through radial and axial movements of the scraper to complete the unloading process, which is called the "XJZ" type.

|

Machine Model |

Inner diameter of drum (mm) |

Maximum speed (r/min) |

Separation factor |

Overall dimension (mm) |

Machine Weight (Kg) |

|

|

Scraper discharge |

XJZ1000-NB |

1000 |

1500 |

1258 |

2200*1550*4155 |

4000 |

|

XJZ1200-NB |

1200 |

1400 |

1315 |

2320*1650*4455 |

5300 |

|

|

XJZ1300-NB |

1300 |

1300 |

1229 |

2686*1750*4655 |

6200 |

|

|

XJZ1400-NB |

1400 |

1200 |

1127 |

2700*1850*4680 |

8500 |

|

|

XJZ1600-NB |

1600 |

1100 |

1085 |

2234*2232*4530 |

10000 |

|

|

XJZ1700-NB |

1700 |

1100 |

1138 |

2300*2360*4680 |

11800 |

|

|

XJZ1800-NB |

1800 |

1000 |

1007 |

2360*2386*4980 |

13600 |

|

|

XJZ2000-NB |

2000 |

900 |

906 |

3160*3086*5360 |

18000 |

|

1. Unmatched Stability and Smooth Operation

The foundational advantage of a Top-Suspended Scraper Discharge Centrifuge lies in its revolutionary structural design. Unlike traditional bottom-driven centrifuges, this model is suspended from an overhead support structure. This configuration allows the entire rotating assembly, including the basket and shaft, to hang freely, aligning perfectly with its center of gravity. This natural self-balancing effect drastically reduces vibration and operational noise, even at high rotational speeds and under uneven feed conditions. The exceptional stability ensures smoother running, which minimizes mechanical stress on components, leading to less wear and tear and a fundamentally more harmonious integration into any production line.

2. Enhanced Product Handling and Gentle Processing

For industries dealing with delicate crystalline structures, fragile biological materials, or valuable products that must not be damaged, the gentle action of a Top-Suspended Scraper Discharge Centrifuge is a critical advantage. The scraping mechanism is precisely engineered to discharge the accumulated solids cake with a gentle, plowing action rather than a aggressive digging or scraping. This ensures that crystalline structures remain intact and product quality is preserved. The combination of controlled centrifugal force and gentle discharge makes this system ideal for products where crystal breakage or product degradation would result in significant value loss or failure to meet stringent purity specifications.